Hydraulic Quick-Connect Couplings

Hydraulic quick couplings provide users with the ability to rapidly connect and disconnect hydraulic hoses to machines or other sections of plumbing. Also called quick-connects or quick disconnects, these fittings allow fluid to flow when the male and female sides are locked together. Conversely, when disconnected, the quick couplings prevent fluid leakage using check valves to block exiting fluid.

In a fluid power system, if the hose or the tube will be asked to connect and disconnect frequently, such as once a week, then chances are a quick connect coupling will pay for itself rapidly by improving productivity. At the beginning, the quick couplings are precisely engineered for specific fluid applications, as the development of hydraulic system in many industries, Their widespread use over many years has yielded a diverse variety of designs to serve not only specific, but general industrial applications as well.

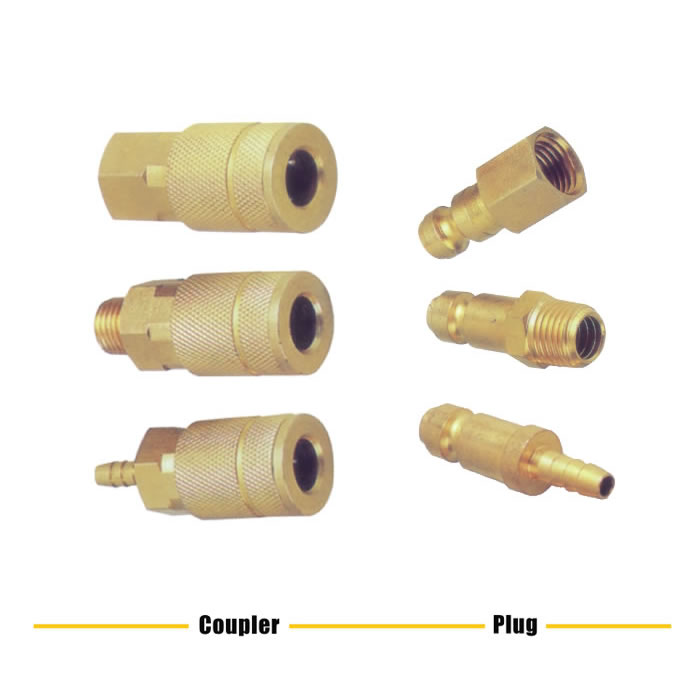

All quick couplings have some elements in common. All have two parts: a plug and a socket. The plug is the male half and the socket is the female half. When connected properly, these parts seal and lock the joint effectively to contain internal pressures and resist any tensile forces that tend to pull the joint apart. The parts are easily disconnected without tools by disengaging a locking mechanism and separating parts.

Where are they used?

The more frequently hoses must be connected and disconnected, the more valuable quick couplings become. They also become more critical as machine productivity increases.

One common application is hydraulic test, if you need to connect the hydraulic test to the product by thread, it will take lots of time to connect and disconnect, use quick couplings, Just a quick push/pull, and the assembly is ready to test.

Are all quick couplers the same?

No.

there are two primary construction styles for hydraulic quick couplings. The check valve style system uses either balls or poppets to block flow from exiting the fitting. When connected, the balls or poppets push against each other, lifting both off their seats to allow flow through the connection.

Flat face couplers employ a more sophisticated interface that, when joined, will push face sections into each other, opening a large flow path through them both.

Thread-to-connect couplers employ male threads on the nipple portion, and when inserted and tightened into the female coupler, squeeze together to open both check valves. Thread-to-connect couplers offer a very high-pressure rating while offering very little flow in return.

What size should I select for my quick couplings?

Quick couplings should be sized based on their flow capacity. It’s a mistake to size couplings relative to the thread size on the hose or fitting to which the coupling attaches. For example, 3/8 in. quick couplings may only flow 4 gpm at 20 psi of backpressure, while the hose itself may flow double that amount.

It’s perfectly okay to use bushings to reduce the larger thread on the coupler down to the size of your plumbing. If your hose thread is larger than your coupling thread, your coupling is likely undersized.

Do all couplings of the same size have the same flow rating?

No.

Flat face couplers offer a more significant flow path with reduced pressure drop. Their interlocking sleeves open an extensive cross-section than poppet-style couplings. The poppets or ball-checks of the latter interfere with the flow path, creating pressure drop.

Why does the price vary so widely with hydraulic quick couplings?

Just like many (but not all) hydraulic components, you get what you pay for. A set of ball-check couplings purchased from a local tractor parts store will offer little in common with the premium flat face couplers.

Inexpensive couplings will corrode more quickly, which is a problem with mobile applications. As previously mentioned, the flow rate will suffer using ball-check couplings, forcing you to oversize the set and pay more regardless. Cheap couplings will also leak more readily, all the while offering little in the way of smooth connection and disconnection. Finally, the poppet style loses oil every time you disconnect it and is also prone to collecting contamination in the female end’s open face.

Premium flat face couplings offer corrosion-resistant parts that are precision-machined to offer the smoothest, most reliable connection. As discussed, their large flow path offers lower pressure drop, so you’re benefited from using a more appropriately sized set. Finally, most flat face couplings offer a twist lock that prevents accidental disconnection should an object hit the sleeve.

Quick Coupling's Valve

In many different designs of quick couplings, either of tow types are used for an application.

Unvalved types have the advantage of low pressure loss through the coupling, but make no provision to prevent fluid from escaping once the coupling is disconnected. However, if pressure drop in the system must be held to a minimum, and fluid draining from disconnected hoses can be tolerated, unvalved couplings would likely be a designer’s first choice.

Obviously, a coupling that does not leak when disconnected would be preferred for probably all applications – all other factors being equal. Incorporating a shutoff valve into one or both halves of the coupling allows fluid to flow through the coupling only when both halves are connected. When the coupling is disconnected, a mechanical link between the coupling halves is broken and causes the valve to close, blocking flow.

When only one coupling half is valved, it usually is located on the source (upstream) end of the joint. Pneumatic systems generally employ this setup: the valved coupling half prevents air loss from the system while the joint is disconnected, the unvalved coupling half allowed downstream air to bleed off.

In hydraulic applications, both coupling halves often are valved. This practice not only minimizes fluid leakage, but also limits the amount of air, dirt, and water that can enter the system. When a coupling is disconnected, air can become trapped between valves and enter the system when the joint is reconnected. So if the hydraulic system cannot tolerate air inclusion, special provisions may be necessary to exclude air. To address these concerns, many manufacturers now offer flat-faced couplings that reduce fluid spillage to a drop or less every time the coupling is disconnected. Futhermore, mating surfaces of each coupling half are flush when the coupling is disconnected. This minimizes air ingression and wiping the mating surfaces clean before reconnecting them.

Valve considerations

While these valved designs offer the convenience of controlled fluid loss, there are tradeoffs. First of all, valved couplings can generate a significantly higher pressure drop than unvalved designs. The amount of this loss depends on the coupling size and design. Pressure drop can be reduced somewhat by oversizing the coupling. There also may be some deviation in pressure drop from one coupling design to another. If pressure drop is a concern, be sure to check manufacturer’s literature for appropriate data.

Other drawbacks to valved couplings include larger size and higher cost. The cost differential will vary according to size and individual design. Generally, couplings designed for low pressure drop, no fluid leakage, and no air entrapment carry a higher price tag. However, manufacturers point out that the price differential is offset by higher productivity gained by not having to clean up fluid spills.

Type of the Longwei Hydraulic Quick Couplings

You May Like

- ISO 7241-A Quick Disconnect Hydraulic Coupler Set Stainless SteelLongwei Auto Parts2022-12-08T14:38:16+08:00

Leave A Comment