Quick Disconnect Fittings For Pneumatic Applications

Tech Archives

May 2, 2024

P

neumatic quick disconnect couplings

Quick connect pneumatic (compressed air) fittings are paired as couplings. Pneumatic couplings provide lightweight tool-to-hose and other pneumatic connections that can be quickly and easily connected, disconnected and reconnected.

The Industrial Interchange quick coupling standard is the most popular and common pneumatic connector type. These are also sometimes called Industrial-Shape or M-Style couplings.

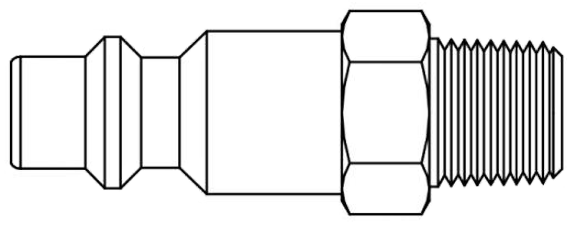

This type of plug has been adopted by all major manufacturers.The couplings that will mate with this plug are either“sleeve”type or “push”type couplings.To identify this plug,look for the 3/16”tip and a V shape,flat bottom ball groove. Complies to ANSI T 3.20.14 dimensions.

3/16”tip / V shape,flat bottom / ball groove

All Industrial Interchange male connectors (plugs or nipples) are engineered to be compatible with all Industrial Interchange female couplers (sockets) with the same body (coupling) size. The body size of Industrial Interchange connectors and couplers is independent of the pipe size or hose inner diameter (ID) they are connected to.

Pneumatic Couplings, Connectors and Couplers

Pneumatic (compressed air) quick couplings are made up of paired fittings. One half of a quick coupling is called the connector (plug or nipple) and the other half is called a coupler (socket). Quick couplings are also called quick-connect and quick disconnect fittings.

Zinc-plated steel quarter inch body size Industrial Interchange coupling. The connector or plug is on the left and the manual coupler or socket is on the right.

Industrial Interchange coupling connector (left) and coupler (right)

Connectors

Connectors (plugs or nipples) for one way shut-off couplings are non-valved. They mate with valved couplers (sockets) to create one way shut-off (single shut-off) connections. Connectors are usually installed on air tools.

Because connectors do not have any valving, they exhaust or vent the compressed air left in the tool or the downstream line when the coupling is disconnected.

Couplers

Couplers (sockets) are usually installed on air supply lines and hoses. Their design incorporates an internal flow shut-off valve. This valve automatically opens when the mating connector (plug or nipple) is inserted. It automatically closes when the connector is removed.

Most common coupler designs use a mechanism with either captive steel balls or locking pawls (pins). These balls or pawls catch and hold on to the locking groove on the mating connector.

Automatic and manual couplers

There are two general styles of pneumatic quick couplers (sockets): automatic and manual.

Automatic couplers

Automatic couplers can be connected and disconnected using a one-handed push-to-connect operation if the coupler is firmly mounted. Simply insert the connector (plug or nipple) into the socket. The locking sleeve automatically slides forward and locks the connector in place. Pulling back the sleeve releases the nipple and disconnects the coupling.

Automatic coupler mechanisms use locking balls, pins or pawls that hold the sleeve pulled back when there is no connector (plug) inserted in the coupling.

Brass quarter inch body size Industrial Interchange couplers or sockets. On the left is a manual coupler and on the right is an automatic coupler.

Manual couplers

Manual couplers require two hands to make or release a connection. To connect manual couplers, pull back the coupler sleeve, insert the connector and then release the sleeve to make the connection. Reversing the process disconnects the coupling.

CAUTION: When disconnecting manual couplings under pressure, it is important to firmly hold both halves of the coupling. This is because residual pressure in the downstream connection could cause hose whip. Hose whip is when a pressurized hose releases from its connection and is allowed to whip around freely. It can lead to personal injury and damage to objects in the immediate area.

Other compressed air applications that benefit from the use of quick connect couplings include

Blow guns

Grease guns

Air compressors

Paint applicators

Cleaning equipment

Drop-down air lines

Summing it all up

Single shut-off pneumatic couplings are a useful, if not necessary, quick connect and disconnect option for air tools and other compressed air applications. Each coupling is made up of a female coupler (socket) fitting paired with a male connector (plug or nipple) fitting.

Single shut-off couplings have a valve built into the female coupler (socket) but not the male connector (nipple or plug). The valve automatically opens when the male connector is mated with or inserted into the female coupler. The valve closes when the male connector is removed. This helps keep the system pressurized.

Industrial Interchange type single shut-off quick connect couplings are only one of multiple air coupling standards. Many of these different standards cannot interconnect. Industrial Interchange couplings are also the most common type of air coupling you will encounter. Because of this, you may find yourself either needing to add Industrial Interchange couplers to a pneumatic application or replace an existing Industrial Interchange fitting.

Leave A Comment