Hydraulic Hose Fittings: The Ultimate Guide

Hydraulic quick couplings provide users with the ability to rapidly connect and disconnect hydraulic hoses to machines or other sections of plumbing. Also called quick-connects or quick disconnects, these fittings allow fluid to flow when the male and female sides are locked together. Conversely, when disconnected, the quick couplings prevent fluid leakage using check valves to block exiting fluid.

Hydraulic fittings can be found in almost every industry, but not all hydraulic hose fittings can do the same job. Given the extent of their usage, it’s important to choose the right kind of hydraulic fitting to suit your application, hose size and assembly.

Whether you are a professional in the industry or just learning the ropes, you need to be able to identify the right hydraulic fitting for the job. We’re here to make it easy for our readers with a complete guide to types of hydraulic hose fittings, their applications and how to use them. Keep reading to learn everything you need to know.

What Is a Hydraulic Quick Coupler?

A hydraulic coupler is a quick, convenient method to attach or detach hoses and fittings in high-pressure hydraulic systems. They provide a fluid-tight seal to maximize the hydraulic system. This coupler type is an ideal tool across industries from agriculture to industrial equipment.

Manufacturers use nonferrous metals like carbon steel, stainless steel, aluminum alloys or brass to design these couplers for durability. Couplers often feature integral crimp sleeves as well as oil-resistant O-rings.

Hydraulic fittings are parts used to connect hydraulic hoses to other components. Hydraulic couplings are used in a variety of machines and equipment across all major industries. They are used in manufacturing hydraulics and assembly lines, water and sewage systems, oil refineries, and construction site hydraulics, to name a few.

There are different types of hydraulic fittings; each one serves a different purpose. They also come in different sizes, materials, types of seals, and temperature and pressure tolerances. For instance, a hydraulic fitting can either allow or prevent the flow of fluid. In some cases, the fittings are dual-use and can do both. But the most important quality of a hydraulic fitting is how effective it is in creating a tight seal.

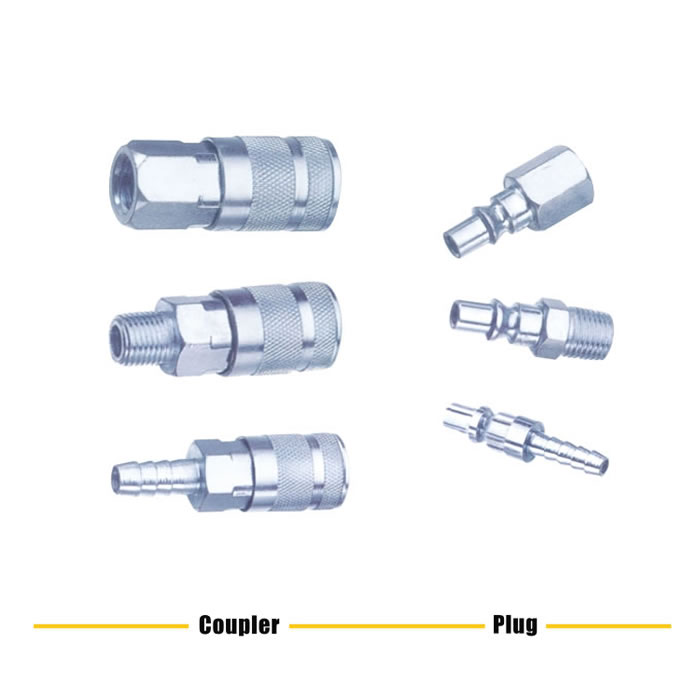

The two main types of hydraulic fittings are crimped fittings and field attachable fittings. As the name implies, field attachable fittings or reusable fittings consist of a socket and a nipple and can be installed anywhere without using a crimper.

A crimped fitting is a permanent fitting that is sealed with acrimping machine. Crimped fittings are much more secure than a field attachable fitting but do need the equipment to make the seal. While many crimping machines are larger units that stay in the workshop, there are also many portable and handheld hydraulic crimpers to bridge the gap between crimp couplings and field attachable fittings.

What Are Hydraulic Hose Fittings Made Of?

Hydraulic fittings can be made from many materials, the most common ones being plastic, stainless steel, or brass. The type of assembly or industry application usually determines what material is suitable.

The most common materials used in hydraulic fittings:

Plastic Hydraulic Fittings – these types are much more resistant to corrosion compared to their metal counterparts. However, they are physically weaker and less durable. This is why they are not preferred for hydraulic applications despite the low cost. Metal fittings are better suited for high-pressure ratings found in industrial applications.

Steel Hydraulic Fittings – these types of fittings are made of steel alloys which means they are far more durable than their plastic counterparts. For instance, carbon steel fittings can withstand temperatures from -53°C up to 260°C.

Stainless Steel Fittings – as the name suggests, these are the stainless steel variant of steel hydraulic fittings. Stainless steel fittings are utilised in situations where they would need to withstand temperatures ranging from -253°C up to 648°C. Their tough nature makes them the choice of fitting for highly corrosive environments. Fittings made from this material are generally rated up to 10,000 psi, with some special designs capable of withstanding up to 20,000 psi. The primary drawback for these is their high price, which usually prompts industries to consider alternatives for less hard-wearing applications.

Brass Fittings – these are not as strong or durable as their stainless steel counterparts. However, they can provide a tight seal that prevents leaks and meet SAE (Society of Automotive Engineers), ISO (International Organization for Standardization), DIN (Deutsches Institute für Normung), and JIS (Japanese Industrial Standards) standards, among others. Brass fittings are rated for temperatures from -53°C up to 204°C, and pressures up to 3,000 psi.

Aluminium Fittings – hydraulic fittings made from aluminium are less common, but do exist and are used in certain applications. They are lighter than steel but are resistant to corrosion. These qualities make them preferable in transportation hydraulics such as the automotive industry.

What Does a Hydraulic Coupler Do?

A hydraulic coupler makes a tight connection for hydraulic fluid to flow between two tools. For example, a construction worker at an assembly workstation might need to switch tools in seconds to remain efficient. The workstation provides one coupling half on every tool and the other half on the air line. Then, the worker can simply swap tools on the airlines with ease.

A tractor operator could use hydraulic couplings to rapidly switch between attachments like a grappler and tree shearer on the same job site. Whatever your application, hydraulic couplers provide a safe and convenient way to move between tools.

Fitting Ends And Connector Types

The three most common fitting ends and connector types for hydraulic fittings are the O-ring, the mated angle, and the tapered thread connectors. Although these are the most popular choices, several other types are used in different and specialised applications.

Since hydraulic fittings vary in how they seal connections, it is important to consider seeking professional or technical advice to avoid leaks or other dangerous scenarios.

The primary fittings and connector types are:

O-Ring Face Seal (ORFS) – hydraulic fittings equipped with this kind of sealing method provide a secure and reliable elastomeric seal preferred for applications with any risk of leaking fluids. They can eliminate leaks in hydraulic systems that operate at pressures that can reach up to 6,000 psi. ORFS fittings can be split into the following types:

Straight ORFS Fitting – a straight screw connection with a male ORFS connection point to male PRT, G, or metric threads.

Elbow ORFS Fitting is an elbow screw connection with an ORFS female connection and an ORFS male connection at an angle.

Tee ORFS Fitting – this is a T-shaped screw connection with three connection ports. One is a female ORFS connection port, with two other male ORFS connection ports.

Cross ORFS Fitting – this is equipped with four male ORFS connection ports and is useful for distribution or combining.

DIN Or BSP – these stand for ‘Deutsches Institut für Normung’ and ‘British Standard Pipe’ and are a type of hydraulic fitting commonly used across Europe.

DIN hydraulic fittings are interchangeable with different brands of fittings. They are used in industrial, construction, and oil applications and industries.

BSP hydraulic fittings have screw threads that conform to BSP standards. These fittings are used primarily for interconnecting pipes and sealing, which is achieved by interlocking the external (male) with the internal (female) thread. These fittings are commonly found in plumbing industries and are widely accepted worldwide except for North America due to the American National Pipe Tapered Thread (NPT) standard.

Mated Angle – hydraulic fittings with an angle seat equipped with either straight or parallel threads for sealing. When the male and female counterparts are threaded together, the threads don’t actually form the seal. Instead, the fitting mechanically creates a seal by bringing the mating angle seats together, making the seal.

Tapered Threads – this type of hydraulic fitting has a male and female thread. Male fittings have their threads on the outside, while female fittings have theirs on the inside. The tapered thread deforms when the male and female fittings are threaded together. This consequently applies pressure on the couplings, which create the seal. Unfortunately, these fittings are prone to shredding and contaminate sensitive areas, which often causes them to be prohibited for use in hydraulic and pneumatic systems. In addition, the lubricity of these fittings has also been known to cause over-torquing.

How To Identify Hydraulic Hose Fittings?

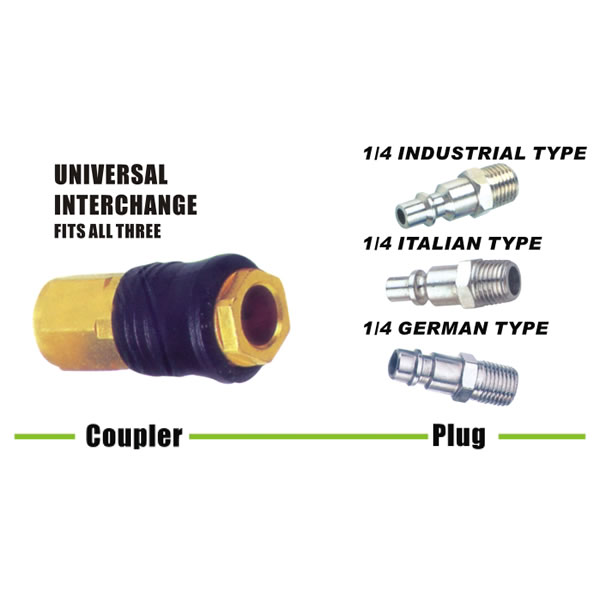

There are two main types of hydraulic couplers — pioneer and flat face couplers.

The pioneer coupler has a male and female end. The male end has a rounded tab that gets pushed back when inserted into the female end. Simply pull the collar back on the female end and insert the male end. The pressure seal allows the hydraulic fluid to move between the connectors.

The flat face coupler is similar to and easier to operate than the pioneer. All you have to do is click the male and female ends together without pulling back the collar on the female end.

There are many different size and shape variants within these two categories. It’s critical to ensure that your organization’s equipment will properly integrate with new machinery that comes with its own hydraulic couplers.

A 3-inch male coupler will not fit into a 2-inch female coupler, and there is no universal standard or adjustment tool to fix this issue. All brands of hydraulic couplers will match each other based on ISO standards, but you cannot match different sizes.

To properly identify the hydraulic hose fitting for the application, determine the type of fitting, match the port connection with that of the hose, and determine the type of seal and fitting design and size of the thread.

1. Determine the type of fitting – check to see if the fitting is crimped or reusable. Newer equipment and connections are usually crimped.

2. Match the port connection with that of the hose – another important part is to make sure that the port connection matches the one on the hydraulic hose. Refer to the table below.

| Port Connection | Hose Connection |

| BSPP (JISPF) | 60 degree NPSM Swivel |

| BSPT (JIS-PT) | 30 degree Flare (Metric) |

| DIN Metric | O-Ring Face Seal (ORFS) |

| ISO 6149 | 24 Degree Flareless (DIN) |

| JIS-B2351 | 30 Degree Flare (BSPP) |

| Metric Taper | 45 Degree Flare |

| NPT-NPTF | 37 Degree Flare |

| SAE Straight Thread | 24 Degree Flareless (SAE) |

3. Determine the type of seal – referring to the physical dimensions and technical characteristics, identify whether it is using an O-Ring, a Mated Angle, or a Tapered Thread. Mated Angles are based on straight and parallel thread types, in which the male and female units will form the seal. Tapered Threads will have the threads on the outside if it is a male unit and on the inside if it is female. Lastly, O-Rings (ORFS) will already include the seal.

4. Determine the fitting design and size of the thread – refer to the list below for the most common and widely used hydraulic fittings.

NPT/NPTF – this is the most commonly used type of thread in North America and is recognisable by its tapered inner diameter and outer diameter. This creates a self-sealing fitting.

BSPT (JIS-PT) – also known as the British Thread Type, is standard fittings adopted internationally for making connections and sealing pipe ends.

Metric Taper – this is the most commonly used thread type in Europe and is known for its precise cylindrical inner and outer diameters.

SAE Straight Thread – a thread type known for its reliability and reusability-has excellent sealing due to its 90-durometer O-rings.

ISO 6149 – this is equipped with a straight thread O-ring port, useful for diagnostic port applications.

JIS-B2351 – this thread type is primarily used as a hose adapter for equipment manufactured in Japan or Korea. These usually come with BSP threads.

DIN Metric – Since this thread type uses the German Industrial Standard, they are popular throughout Germany and the majority of Europe.

BSPP (JIS-PF) – These are BSPP connectors that follow the standard British thread dimensions.

4-Bolt Flange – these come in a variety of types, catering to either standard or heavy-duty applications.

How Do You Choose the End Fittings For a Hydraulic Hose?

The criteria for choosing the right end fittings for hydraulic hoses are size, material, temperature, pressure, application, and assembly. The proper assessment of these criteria is critical to ensure the safety and reliability of the connections. Each of the factors mentioned above are detailed below:

Size – when it comes to the size, the important measurements to consider are the internal and external diameters of the hydraulic fittings. The diameters have to be compatible with that of the hydraulic hose. Fittings over or under-sized won’t be sealed properly and cause the connection to fail or leak.

Material – different materials have different properties, which affect and determine the compatibility with the fluid. As such, making sure that the fitting is compatible with both the hydraulic fluid and the working environment is critical. Determine both and choose between brass, aluminium, steel, or stainless steel. The most widely-used sealing materials are O-rings made from NBR (Nitrile).

Temperature – aside from ensuring that the different materials that make up hydraulic fittings are resistant to the operating temperatures, the type of fittings should also be considered.

Pressure – the amount of pressure the hydraulic fitting is subjected to differ across varying industries and applications. Make sure that the fittings are rated for the pressure range required. Operating beyond the rated pressure may cause leaks and even danger to people in the working environment.

Application – depending on the industry or application, the fittings could be used for either mixing or distributing. As such, hydraulic fittings such as the T-shape and the cross-shape come into consideration.

Assembly – hydraulic systems that require frequent connections and disconnections of the hose or tube should consider quick-connect fittings. For instance, hydraulic compression fittings can also remove the need to weld or solder the fitting. It uses a compression nut that tightens against the ferrule, creating a tight seal.

Permanence – Needing a permanent fitting or one that can be removed and changed frequently will affect the fitting style you choose. If this fitting is going to be changed often, a field attachable fitting will work just fine, but if you need something permanent and strong, using a crimping machine to crimp your fitting permanently is the perfect option.

Aside from this criteria, the hydraulic fluids used in the industry should also determine what type of coupling is best. Not all fittings are compatible with all hydraulic fluids. The primary hydraulic fluid types are petroleum-based, water-based or synthetic-based fluids.

Leave A Comment