LEARN MORE ABOUT QUICK COUPLERS

Quick couplers, also known as quick connectors or quick release couplings, are devices used to rapidly connect and disconnect hydraulic or pneumatic lines fitting. They provide a convenient and efficient means of connecting hoses, pipes, and other components without the need for tools or complicated procedures. For this reason, they are especially useful in critical or time-dependent production applications where speed is key. Quick couplers also save valuable time when used to construct or tear down plumbing systems.

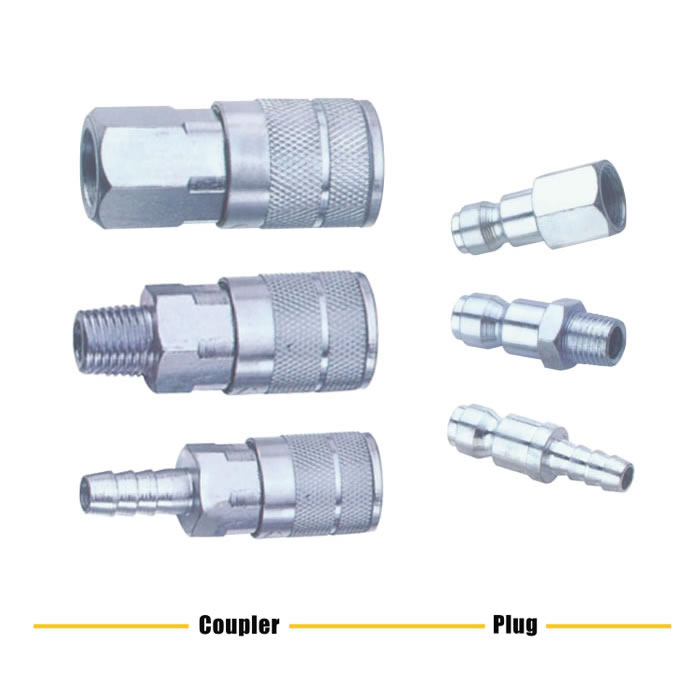

Quick couplers consist of two main parts: a male adapter and a female coupler. The male adapter typically has a barbed or threaded end that fits into the hose or pipe, while the female coupler has a corresponding opening or socket. When the male adapter is inserted into the female coupler, they securely lock together, forming a tight and leak-proof connection.

The primary purpose of quick couplers is to enable easy and fast connection and disconnection of fluid lines, such as those used in hydraulic systems, pneumatic systems, and various industrial applications. They allow for swift equipment changes, component replacements, or maintenance tasks without the need to drain or depressurize the system.

Quick couplers are available in a variety of designs and configurations to suit different applications and fluid types. Common types include push-to-connect couplers, camlock couplers, and twist-lock couplers. Each type has its own specific mechanism for connecting and disconnecting the couplers.

Overall, quick couplers offer convenience, time-saving, and increased efficiency in various industries where fluid transfer is involved. They enhance productivity, reduce downtime, and improve safety by minimizing the risk of leaks and spills during connection and disconnection processes.

Quick Coupler Connection Types

When selecting quick couplers, the buyer must consider the connection types of both the quick coupler end and the ends connecting to the rest of the system.

Quick couplers, also known as quick-connect fittings or quick-release couplings, are used to rapidly connect and disconnect fluid or gas lines in various industries.

There are several common connection types for quick couplers, including:

Quick Coupler Connections

-

Push-to-Connect: This type of quick coupler allows for easy connection by simply pushing the tubing or hose into the coupler. The internal mechanism securely holds the connection in place until it is manually released.

-

Threaded: Threaded quick couplers use male and female threaded connections to join the components. They typically require a few turns to securely connect and disconnect. Threaded couplers are commonly used in hydraulic and pneumatic applications.

-

Cam and Groove: Also known as camlock couplings, this type of quick coupler uses a cam mechanism for connection. The male adapter and female coupler have complementary grooves and arms that lock together when rotated, providing a secure and leak-tight connection. Cam and groove couplings are frequently used for transferring fluids such as water, chemicals, and petroleum products.

-

Snap-Tite: Snap-Tite couplings utilize a ball-locking mechanism to connect and disconnect. The male and female parts have ball bearings that snap into place when aligned, creating a secure connection. To disconnect, the sleeve is pushed back, releasing the balls. Snap-Tite couplings are commonly used in hydraulic systems.

-

Claw or Chicago-style: This type of quick coupler features a pair of interlocking claws on the male and female ends. The claws engage when the coupler is inserted into the socket, creating a secure connection. Claw couplings are widely used in compressed air and water applications.

-

Dry Disconnect: Dry disconnect couplings are designed for applications where spillage or leakage must be minimized. They feature a valve mechanism on both the male and female ends that prevents fluid loss when connecting or disconnecting. Dry disconnect couplings are commonly used for hazardous chemicals, petroleum products, and liquid food products.

- Ball and sleeve connections employ a "ball" or male end which fits into a female outer sleeve. The sleeve can be pulled back by the user for retraction in order to connect and disconnect the halves of the coupler.

- Cam-lock fittings are connected using tabs on the female half which fold down to lock the receiver in place after it is inserted. These fittings allow for quick, secure connections of hoses to tanks or other hoses. They are used in many heavy-duty hose applications such as fire hose and sludge/sewage pumping.

- Luer locks are sleeve fittings that afford simple, effective connections via a quick twisting action. They are generally made for short, single usage. They are most commonly used in medical and laboratory applications.

- Twist or bayonet fittings incorporate a twist motion (1/8 - 1/4 of a turn) that engages and disengages the connection.

System Connections

When selecting quick couplers, another important distinction is what the other end of each piece of the quick coupler connects to. There are an assortment of different connection types available for attachment to a variety of systems and vessel types.

-

Compression fittings are fittings which connect tubes using compression on a gasket, ring, or ferrule. The compression typically is made by tightening a nut onto the connection threading over the tubing and ferrule. Quick coupler ends made for compression connections have open female threads with cavities designed to accept ferrules or compression rings.

In specific applications, quick couplings may be required to connect to a flange at one end of the adapter. Flange fittings are rims, edges, ribs, or collars with flush surfaces.

-

Plain end connections are used to allow connectors to be welded, brazed, soldered, or glued to the associated pipe or tube.

-

Threads are the most common connections used for pipe, tube, and hose fittings, and thus are standard for most quick coupler adapters. Each half of the quick coupler typically contains a separate gender of thread.

Quick Coupler Sizing

Quick coupler sizing is determined by the pipe, tube, or hose diameter that the adapter connects to. For example, a 1/2" quick coupler is designed to connect to a pipe with a nominal size of 1/2 inch. Diameter sizes are measured in millimeters (mm) according to the Metric system or inches (") according to the U.S. customary system.

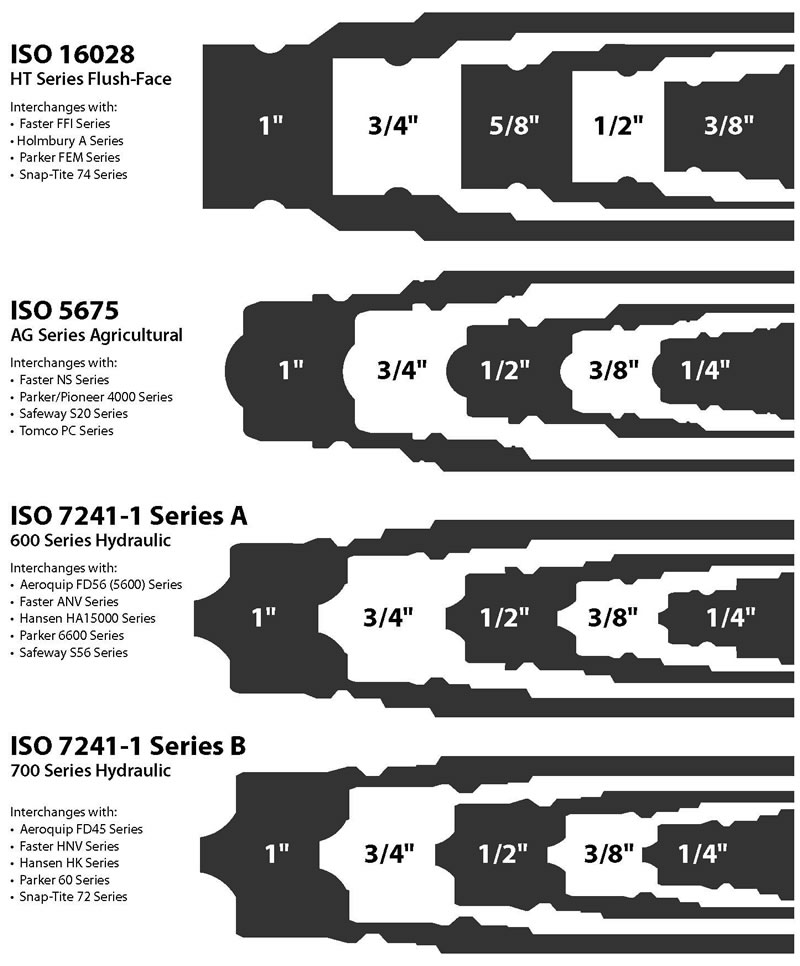

Profiles of male nipples help you to identify four popular styles of hydraulic quick disconnect couplers in nominal sizes ranging from 1/4" to 1". Nominal sizes represent intended hose or tube sizes, not the actual diameter of the coupler. For actual dimensions, print this page actual size and compare the profile drawings to your existing equipment.

coupler sizes shown here are nominal only. To identify your existing hydraulic quick couplers, match the male coupler to one of the outlines show below.

Quick Coupler Materials

The materials for quick couplers are typically selected based on the fluids being transported through the system. Other selection factors include cost, flexibility, environmental conditions, and required pressure ratings. Material choices include different types of plastic or metal.

Common metals include:

-

Aluminum - lightweight and corrosion resistant. Aluminum is commonly used for plumbing and is the preferred fitting material for aluminum tubing. By itself, aluminum has low tensile strength and is used when high corrosion resistance is needed. It is alloyed with zinc, copper, silicon, manganese, and/or other metals to improve its strength and hardness.

-

Brass - strong, durable, and corrosion resistant, with high temperature ductility and good conductivity. Brass is an alloy of copper and zinc, and is a commonly used quick coupler material because of its machinability and its excellent performance properties. Brass fittings can have various protective or decorative finishes which should match the finish of the tubing.

-

Cast iron - strong and highly abrasion resistant. Cast iron fittings and tubes are used primarily in building construction for sanitary, storm drain, waste, and vent tubing applications because of their resistance to abrasive materials like sand, gravel, solid wastes, and debris.

- Copper- extremely corrosion resistant with excellent conductivity. Copper fittings are important for many plumbing and heating applications, and are commonly used for residential water supply lines. Copper fittings are usually used in conjunction with copper tubing, and come in either soft or rigid forms. Soft or ductile copper is easily bent and maneuvered, and is the only type suitable for flare connections. Rigid copper is not bendable and requires directional fittings to go around corners and obstacles.

- Steel - durable and strong, with a high resistance to heat. Steel is an alloy of iron and carbon - it is commonly alloyed with other metals to improve its corrosion resistance and durability. It is used in both commercial and industrial applications for carrying water, flammable gases, and other fluids. Galvanized steel is coated with zinc for rust and chemical corrosion resistance. Carbon steel is alloyed with higher levels of carbon for increased durability and strength.

- Stainless steel- relatively strong with excellent chemical and corrosion resistance. Stainless steel is an alloy of steel that contains over 10.5% chromium, providing excellent corrosion resistance for sanitary applications and those dealing with aggressive fluids and materials. It is a common choice of material for quick couplers.

Quick Coupler Application

- Chemical fitting - Chemical quick couplers may be designed for specific chemicals such as fuel, oil, solvents, acids, bases, etc.

- Gas fitting - Gas quick couplers are specifically designed for explosive and noxious gases such as propane and phosgene.

- Hydraulic fitting - Hydraulic quick couplers are designed and rated specifically for hydraulic lines. Of particular importance for these quick couplers are high pressure ratings.

- Pneumatic fitting - Pneumatic quick couplers are specifically designed for use in compressed air lines and pneumatic systems.

Sanitary / food-grade fitting - Sanitary and food-grade quick couplers are designed and constructed for use in sanitary applications such as the food, beverage, medical, and pharmaceutical industries. - Water fitting - Water quick couplers are rated for use with potable water, typically pressurized, for industrial, municipal, and consumer use.

Longwei Quick Connect Couplings

You May Like

- Air Duster Blow Gun AGQ-07 1/4″ FNPT Nylon Adjustable Flow RateLongwei Auto Parts2022-02-16T10:42:50+08:00

Leave A Comment