Hydraulic Ball Valves - How Does The Ball Valve Work

Hydraulic ball valves are specialized industrial valves used to direct and control fluid in hydraulic systems. These valves are typically constructed from materials like steel, stainless steel, or brass, and they often operate at high pressures and temperatures. As the valve handle is turned to open the valve, the ball rotates to a point where part or all of the hole through the ball is in line with the valve body inlet and outlet, allowing fluid to flow through the valve. When the ball is rotated so the hole is perpendicular to the flow openings of the valve body, the flow of fluid stops.

Ball Valves come in various configurations and options, with different function capabilities. Additionally, hydraulic ball valves can be used beyond hydraulics—for applications like water and compressed air in high-pressure cleaners.

If you need more specific information or have any other questions, feel free to ask!

How do hydraulic ball valves work?

Hydraulic ball valves operate using a simple yet effective mechanism. Here’s how they work:

Ball Valve Structure:

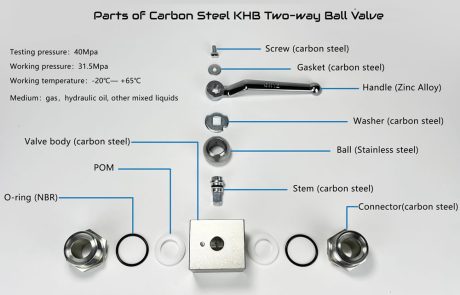

- Hydraulic ball valve consists of several key components:

- Valve Stem: Connects the actuator (such as a handle or electric / pneumatic actuator) to the ball.

- O-rings : These prevent leakage around the valve seat.

- Housing : Supports and protects the internal components.

- Ball : The hollow ball allows fluid to flow when the valve is open.

- Seat : Supports and seals the ball.

What are the advantages of using hydraulic ball valves?

Quick Operation:

- Ball valves operate with a quarter-turn motion, allowing for rapid opening and closing.

- This quick action is essential in emergency shut-off situations.

Low Pressure Drop:

- The full-bore design of ball valves minimizes pressure drop across the valve.

- Fluid flows through the valve without significant obstruction.

Durability:

- Hydraulic ball valves are robust and resistant to wear.

- They handle high pressures and temperatures effectively.

Leakage Prevention:

- The tight seal provided by the ball and seat minimizes leakage.

- O-rings further enhance sealing performance.

Versatility:

- Suitable for various media, including hydraulic fluids, water, and gases.

- Available in different materials (steel, stainless steel, brass) for compatibility.

Easy Maintenance:

- Simple design with few moving parts.

- Maintenance involves lubrication and occasional replacement of seals.

You May Like

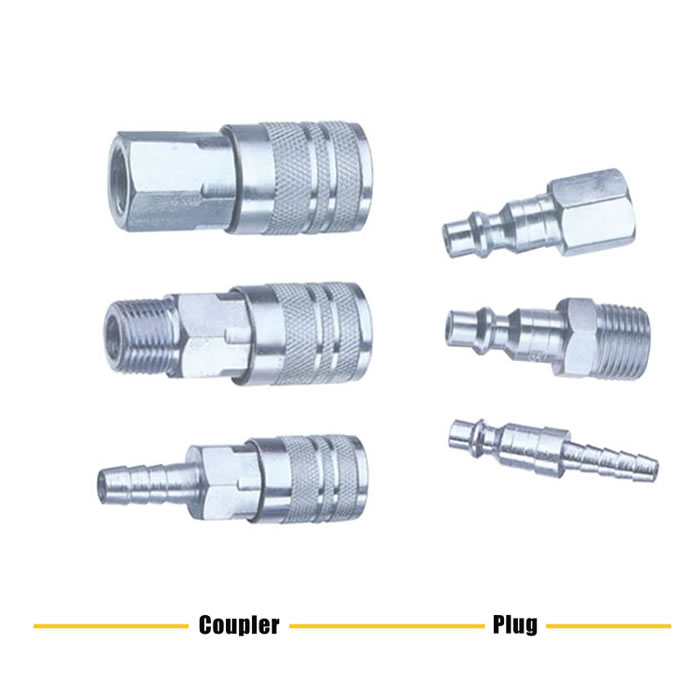

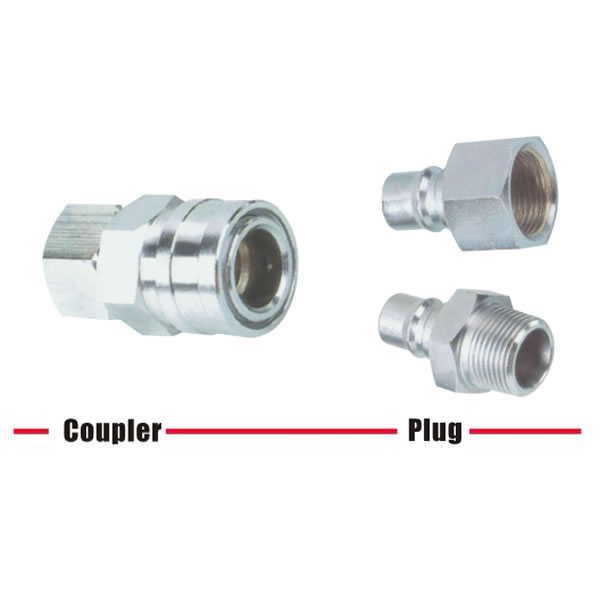

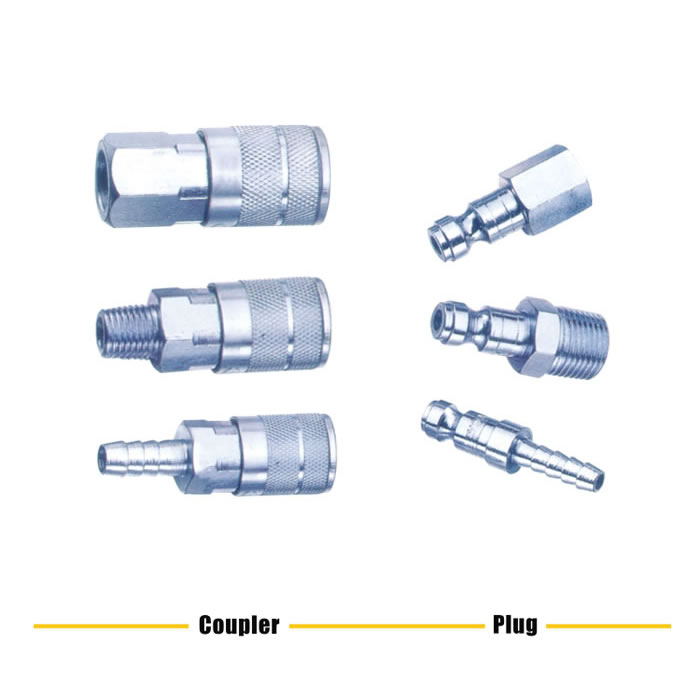

- Nitto Type Quick Disconnect Coupling 400SF/PF/SM/PM/SH/PHLongwei Auto Parts2022-02-18T16:59:28+08:00