What are Pneumatic Pipe Fittings?

Pneumatic Pipe Fittings

Pneumatic fittings are essential components in pneumatic systems that connect sections of pipe, tube, and hose in compressed air or gas pipelines. these are distinguished from hydraulic fittings by their tighter seals and lower pressure standards. They’re commonly found in pneumatic logic control and instrumentation systems.

Pneumatic pipe fittings facilitate the controlled flow of air or gas and are designed for quick assembly and disassembly while providing a tight seal. They play a crucial role in ensuring efficient and reliable operation of pneumatic systems.

pneumatic fitting, in general, is any connector intended to connect components or devices in a sealed and pressurized dry-air arrangement.

Today, pneumatic pipe fittings are used in a wide range of sectors and applications, from assembly and production line settings to various industrial machines, construction, handheld gadgets, and workbench equipment. In many professional situations, the power of a pneumatic system might prove to be more dependable, versatile, cost-effective, and safe than a similar configuration powered by various electric motors and actuators.

Types of Pneumatic Pipe Fittings

- Push-to-Connect Fittings: These fittings allow easy and quick connection without the need for tools. They feature a push-in mechanism that securely holds the tubing in place.

- Compression Fittings: These fittings use a threaded nut and ferrule to create a tight seal around the tubing.

- Barbed Fittings: Hose Barbed fittings have ridges or barbs that grip the tubing, ensuring a secure connection.

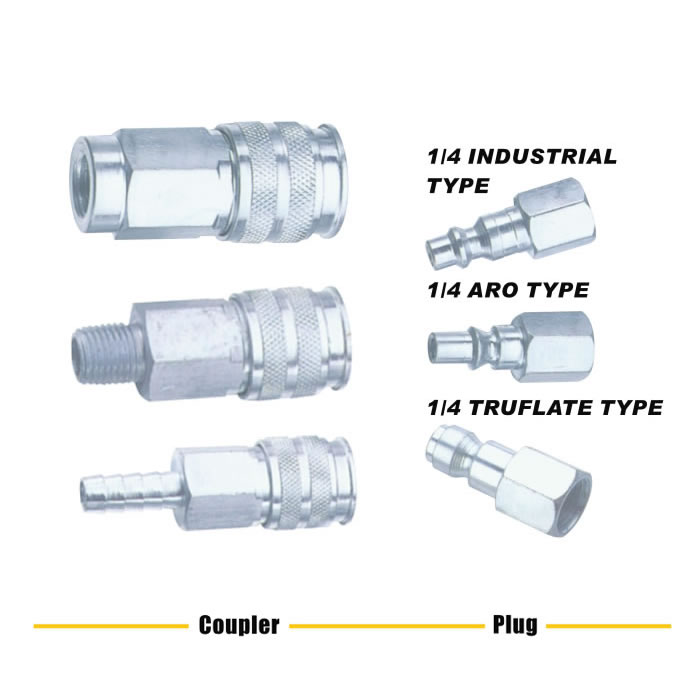

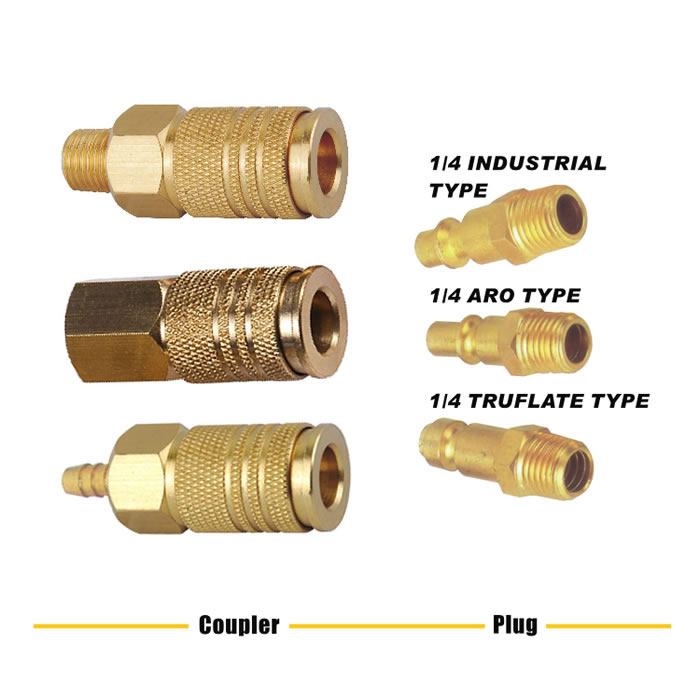

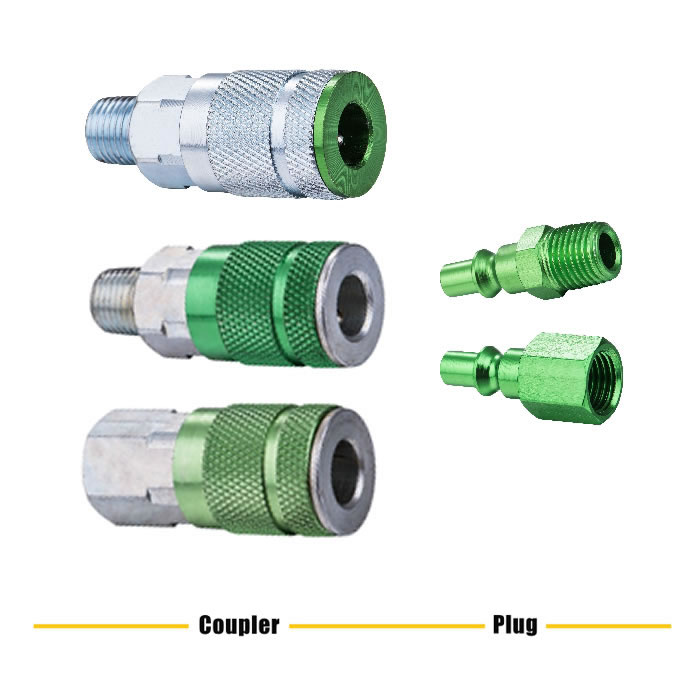

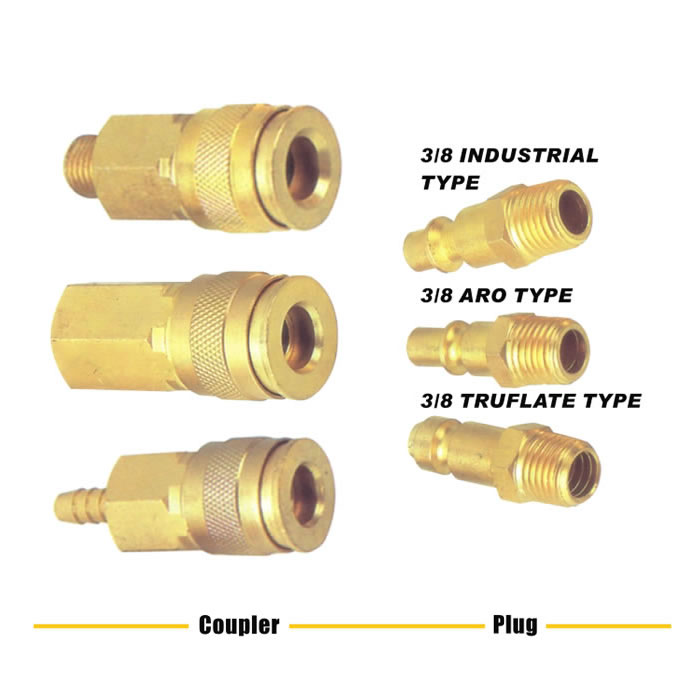

- Quick-Disconnect Couplings: These allow rapid connection and disconnection of components, ideal for applications where frequent changes are needed.

- Threaded Fittings: Threaded fittings have male or female threads and require tightening with a wrench.

- Flare Fittings: Flare fittings create a seal by compressing the tubing against a flared surface.

- Bulkhead Fittings: These fittings allow passage through walls or panels.

- Manifolds and Tees: Used for branching or distributing air flow.

- Flow Control Valves: These fittings regulate airflow by adjusting the opening.

- Check Valves: Prevent backflow in the system.

Quick Disconnect Coupling for Pneumatic Fittings

Working principle of pneumatic pipe fittings

- Pneumatic fittings are frequently built for certain temperatures, and the application defines pressure ranges.

- The operational pressure range refers to the pressure classes, or pressure ranges that the fitting was designed to work in. In most cases, the operating pressure is expressed in pounds per square inch (psi). The fitting may fail if used above or below this rating; for example, it may break, leak, or lose its seal).

- The operational temperature range, given in degrees Celsius (°C) or degrees Fahrenheit (°F), is the temperature range or temperature classes the fitting was designed to work. The fitting may fail if you operate it above or below this grade.

- Other features of pneumatic fittings may be added to provide the capability necessary for specific applications.

- Bulkhead fittings are tube connectors on both sides of a barrier put in a wall or bulkhead.

- Expansion joints and couplings bring tube sections together and allow for movement due to service stress, load, or temperature cycles.

- Fittings with a liner are made with an integral lining. Linings are commonly created of tailored polymers for use with process materials or in applications where media sanitation is critical, such as food processing.

- Surface treatment, plating, or coating on plated fittings improves thermal properties, corrosion resistance, chemical endurance, or other desirable surface qualities.

- One or more fitting ends can swivel or revolve thanks to the swivel function.

- The most basic element of pneumatic fittings can be addressed: adequate sizing. Because larger or undersized parts are either completely incompatible or seal or join inefficiently, proper sizing of pneumatic fittings is critical to an excellent fitting preference.

Pneumatic Pipe Fittings Materials

Pneumatic fittings are available in various materials, including brass, stainless steel, plastic, and aluminum. The choice depends on factors such as compatibility with the working medium, corrosion resistance, and cost.

You May Like

- Nitto Type One Touch Quick Coupler 22SF-N1/SM/PF/PM/SH/SP/PH/PP-N1Longwei Auto Parts2022-02-18T16:57:28+08:00

Leave A Comment