Quick Release Coupling Types

What are Quick Release Couplings?

Quick Release Couplings, also known as Quick Disconnect Couplings, are a type of fluid transfer device that allows for easy and fast connection and disconnection of hoses and pipes. These couplings are commonly used in various industries and applications, including hydraulic systems, pneumatics, automotive, and manufacturing.

Quick Couplings are often hand operated and therefore conveniently negate the need for tools or machinery. When used correctly, the couplings reliably secure a connection and resist any pressures and forces that can break it apart.

How do Quick Release Couplings Work?

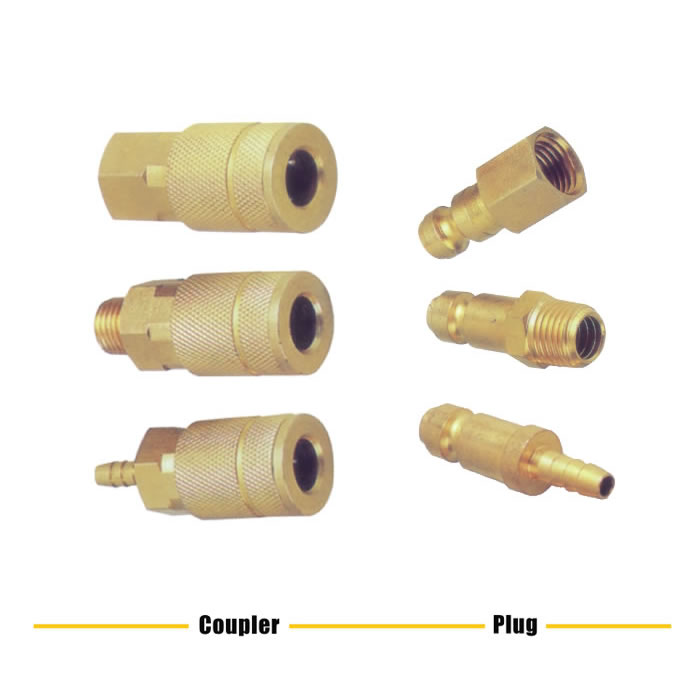

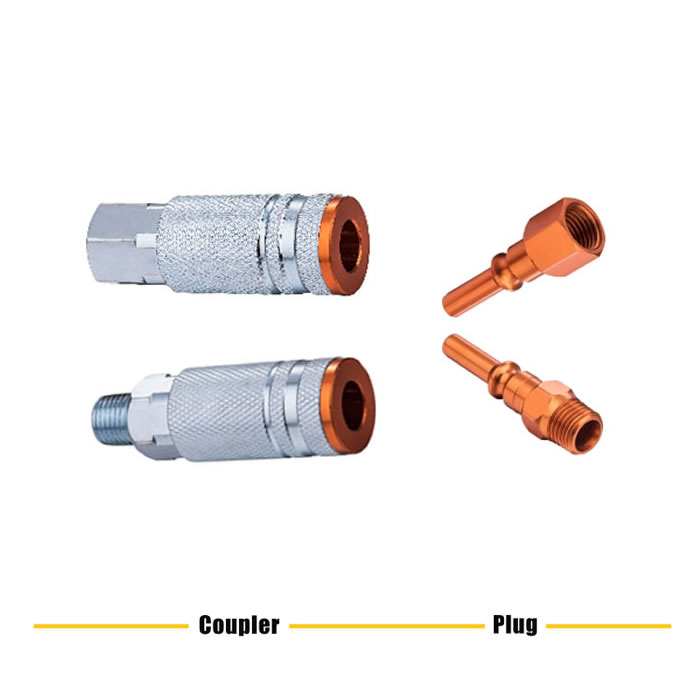

Quick release couplings consist of two primary components: a male part (nipple or plug) that attaches and fits into a female part (coupling or socket). Depending on the quick release coupling type, there are many different ways in which a plug can be secured and locked into the socket.

Where are Quick Release Couplings Used?

Quick release couplings find applications in various industries due to their efficiency and ease of use. Let’s explore some common areas where they are used:

Pneumatics Fitting

- Pneumatic systems rely on compressed air or gas. Quick release couplings enable quick changes in pneumatic lines.

- They are commonly used in pneumatic tools, air compressors, and automated production lines.

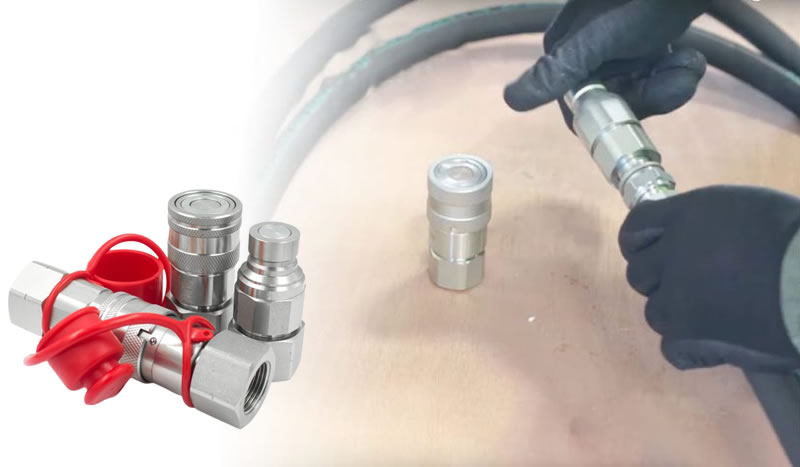

- Quick release couplings are extensively used in hydraulic systems. They allow for rapid connection and disconnection of hoses, making maintenance and repair tasks more efficient.

- Applications include construction machinery, agricultural equipment, and industrial hydraulic systems.

Hydraulic Systems

Manufacturing and Industrial Processes

- Quick release couplings play a vital role in assembly lines and manufacturing processes.

- They allow for swift assembly and disassembly of equipment, reducing downtime.

- Applications include robotics, conveyors, and material handling systems.

In vehicles, quick couplings are employed for various fluid connections:

- Fuel Lines: Connecting fuel hoses securely.

- Air Conditioning Systems: For refrigerant lines.

- Brake Systems: Ensuring reliable brake fluid connections.

Automotive Industry

Chemical and Pharmaceutical Industries:

- These couplings are used for transferring chemicals, solvents, and pharmaceutical liquids.

- Their quick-connect feature ensures efficient batch processing and cleaning.

Agriculture and Irrigation

- Quick couplings are essential for connecting hoses in irrigation systems.

- They allow farmers to quickly set up and dismantle irrigation lines.

Aviation and Aerospace:

- In aircraft maintenance, quick release couplings simplify fluid line connections.

- They are used for fuel, hydraulic fluid, and pneumatic lines.

Marine Applications:

- On ships and boats, quick couplings facilitate fluid transfer between different systems.

- Examples include fuel lines, water supply, and hydraulic systems.

Laboratories and Research Facilities:

- Quick release couplings are used in scientific equipment and lab setups.

- They allow researchers to quickly change experimental setups.

Firefighting Equipment:

- Fire hoses and nozzles often use quick release couplings.

- Firefighters can swiftly connect hoses during emergencies.

Quick Release Coupling Types

Owing to their ease of use, reliability, durability and versatility, quick release couplings can be used across a range of industries and in a number of applications. Some of the most common quick release coupling types are described below.

Ball-Lock type quick release coupling is the most commonly used quick release coupling type and has a wide range of uses. It works when a sleeve is pulled back on the socket which allows a group of balls lining the socket to move outward giving clearance for the plug. The plug, with appropriately grooved holes, is placed in the socket and the spring loaded balls push back into place when the sleeve is released which effectively locks the connection in place.

In vehicles, quick couplings are employed for various fluid connections:

- Fuel Lines: Connecting fuel hoses securely.

- Air Conditioning Systems: For refrigerant lines.

- Brake Systems: Ensuring reliable brake fluid connections.

Cam-Lock

Roller-lock Couplings

Roller-Lock quick release coupling type works as the tapered plug begins pushing rollers within the socket outward. Once inserted the required distance the rollers simply push back in, locking the plug into place.

Bayonet Coupling

Bayonet quick release coupling type works through a push then twist motion of the plug into the socket. The plug features lugs that fit into slots of the socket sleeve. As the plug is pushed into the socket the lugs enter the slots and then when the twist motion is initiated plug and socket lock into place. Twisting the plug in the opposite direction will release the connection.

Pin-Lock Couplings

Pin-Lock quick release coupling type is one of the easiest to operate, as pushing the ramped plug into the socket joins the connection. As the plug enters it pushes back pins within the socket. Once inserted far enough, the spring loaded pins lock the plug into place. Pulling back a spring loaded sleeve allows the pins to move back out releasing the connection.