Nylon Air Tubing: A Versatile Solution for Pneumatic Systems

Nylon Tubing Air Hose Pipe

Nylon air tubing is a flexible and durable conduit used for conveying air and other gases in various applications. Its unique properties make it an excellent choice for pneumatic systems, air brake tubing, and industrial settings. In this article, we’ll explore the features, advantages, and common uses of nylon air tubing.

Material Composition

- Nylon tubing is constructed from abrasion-resistant, heat-resistant, and fuel/oil-resistant nylon.

- Unlike some other plastics, it does not contain plasticizers.

- The tubing is available in both clear and black variants.

Properties

- Chemical Resistance: Nylon tubing exhibits excellent chemical resistance.

- UV Light Resistance: It is also resistant to UV light.

- Low Water Absorption: The clear and black flexible tubing has low water absorption properties.

Applications:

Air Brake Tubing

Nylon air tubing is commonly used in air brake systems for vehicles. Its flexibility and kink resistance ensure reliable performance even in tight spaces.

Pneumatic Systems

In pneumatic systems, nylon tubing serves as a conduit for compressed air. Its smooth interior minimizes pressure drop, enhancing system efficiency.

Industrial Applications

Nylon tubing finds applications across various industrial markets:

- Manufacturing: Used in assembly lines and automated machinery.

- Automation: Ideal for robotic arms and control systems.

- Packaging: Conveys air for packaging equipment.

- Laboratories: Used in scientific instruments and testing setups.

Advantages

- Flexibility: Nylon tubing is flexible, making it suitable for tight spaces.

- Kink Resistance: It resists kinking, reducing the need for rework during installation.

- Pure Air Systems: There’s a specific type called Nylon Pure Air Tubing that is ideal for pure air and gas distribution systems.

How to choose the right compressed air hose for your application

To make the most out of your pneumatic tools, choosing a quality hose is essential to ensure stable air pressure.

Here is a quick and easy guide on the factors you should consider in order to select the right air hose for your application.

Air Hose length

When selecting an air hose, you should always consider your application and total distance between the compressor system and where you will be using the air tool and how much movement you will need.

Air Hose Size

Hose specifications usually list both the hose Outer Diameter (O.D.) and the Internal Diameter (I.D.). However, hose size refers to the hose I.D., rather than the hose O.D.

Common hose sizes are 7 mm (1/4 in), 8 mm (5/16 in), 10 mm (3/8 in) and 13 mm (1/2 in). To maintain adequate airflow, you must ensure that the Hose I.D is not too small for the tools CFM requirements as this will affect your tools performance.

Air Hose Maximum working pressure

This will depend on the maximum pressure relevant to your air supply. The maximum working pressure of the hose must be equal or greater.

The air hose specification may also list the burst pressure, which is the maximum pressure before the hose will rupture. Most hoses offer a 3:1 Safety Factor, this means if the hose is rated at 21 bar / 300 psi working pressure, the burst pressure will be 63 bar / 900 psi. You should not use the burst pressure as an indication that the hose can be used above the maximum working pressure, the burst pressure is for manufacturing test purposes only.

Type of air hose (Standard or Coiled)

There are two types of hoses, Standard or Coiled, your application will determine which type of hose you require.

The material of the hose will affect the flexibility, weight, longevity, and performance therefore you will also need to ensure that the material is suitable for your application.

Hose End Fittings

Ensuring that you select the right fittings and connectors for your system is critical to achieve a good seal and optimum air tool performance.

For your convenience LONGWEI also has a range of hose assemblies, complete with couplings and adaptors – investing in a LONGWEI air tool hose saves the time and expense of buying expensive crimping equipment – you can simply plug in and go.

Replacing your hose

Hoses naturally wear over time, the service life depends on several factors including the hose’s quality, material, frequency of use and maintenance. It is important to inspect your hose and fittings for damage regularly and before use. If there is a defect, you will need to replace the hose.

Inflator tool accessories include:

1x 3 in 1 Tire Inflator with Gauge

1x Air Blow Gun

1x Safety Nozzle

1x Tapered Nozzle

1x Rubber Nozzle

2x Inflation Needles

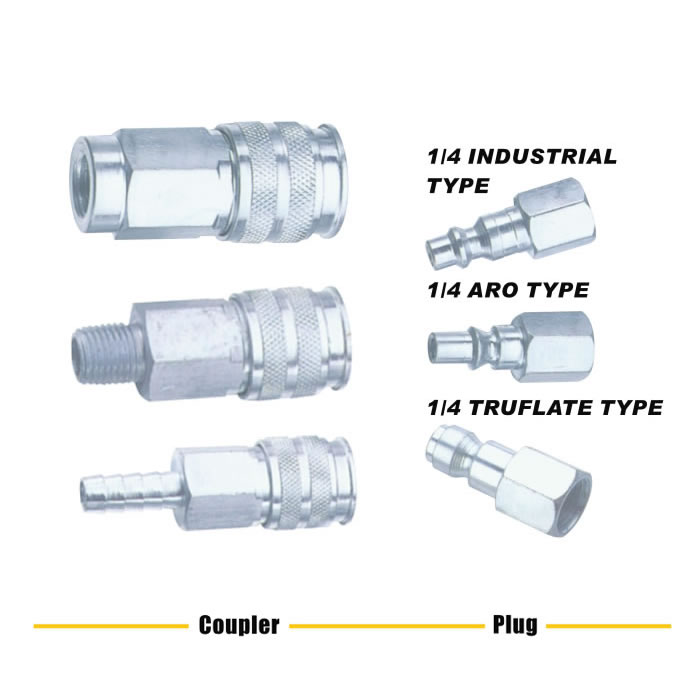

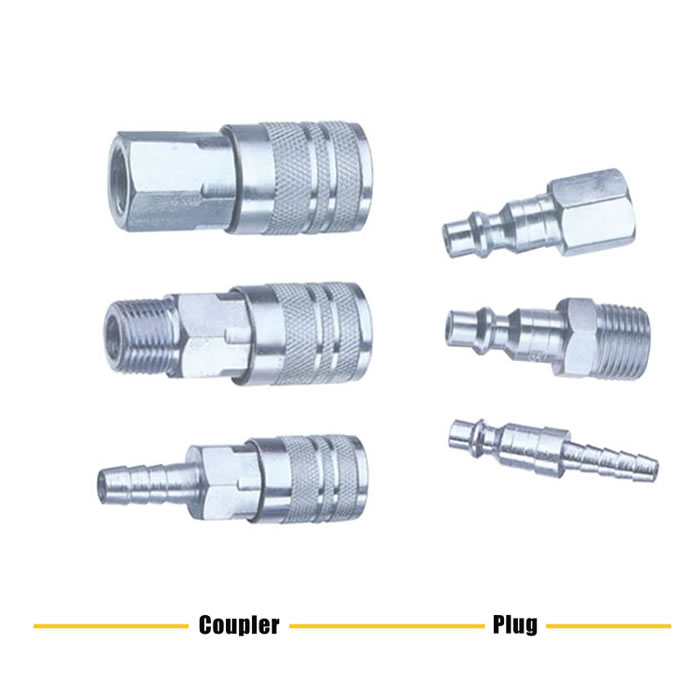

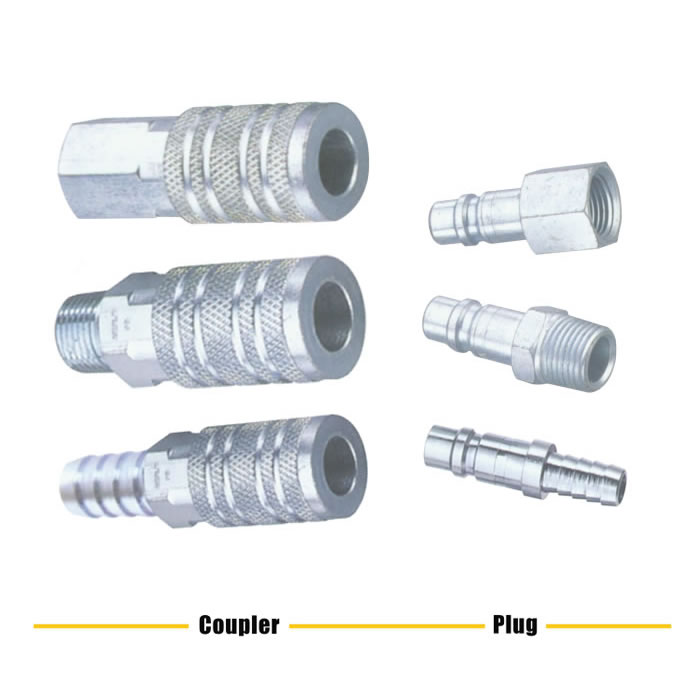

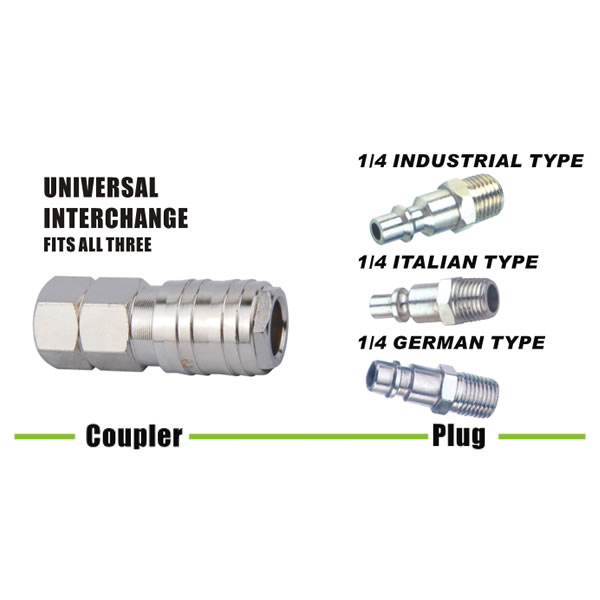

2x 1/4" Industrial Steel Quick Female Coupler

2x 1/4" Industrial Steel Quick Female Plugs

2x 1/4" Industrial Steel Quick Male Plugs

1x Swivel plug

1x 1/4"-18NPT Male Connector

1x 1/4"-18NPT Female Connector

1x Teflon Tape

3-IN-1 INFLATOR GAUGE

Inflating, deflating and checking tire pressure are all in one gauge. It has a 12 inch red heavy duty flexible air hose with a standard 1/4 inch NPT female inlet, measuring 20PSI to 120PSI. Also has zinc cast alloy body with heavy duty brass internal parts, 6-inch chrome plated dual head chuck also included in the package.

Multifunctional Heavy Duty Air Blow Gun

This heavy duty air blow gun comes with 5 different tips for various usage. The safety tip for easy project clean-up. The rubber tip to avoid scratches on fine surfaces. The tapered tip to inflating pool toys and air mattress. The inflation needle tip for inflating sport balls.

10-Piece Heavy Duty 1/4" Industrial Steel Air Hose Fittings

Quick Couplers and plugs are made of hardened steel plated to resist rust and long time use. Recommended use with thread seal tape(Included)