What are Pneumatic Couplers? How They Work?

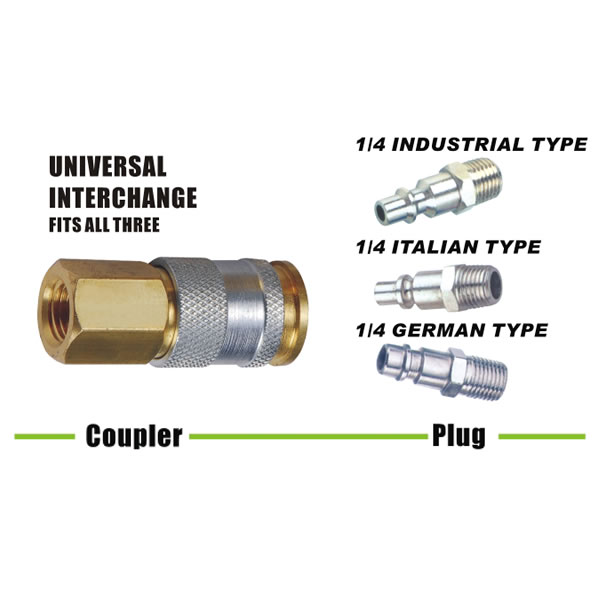

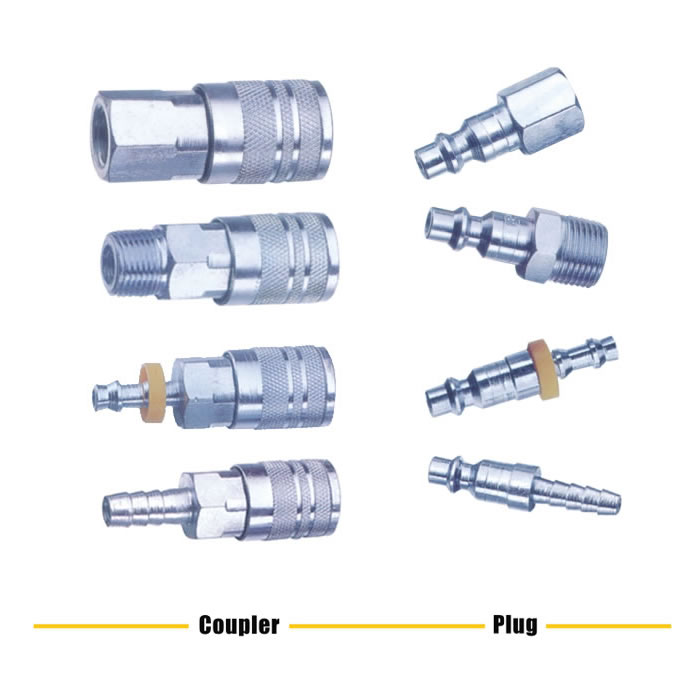

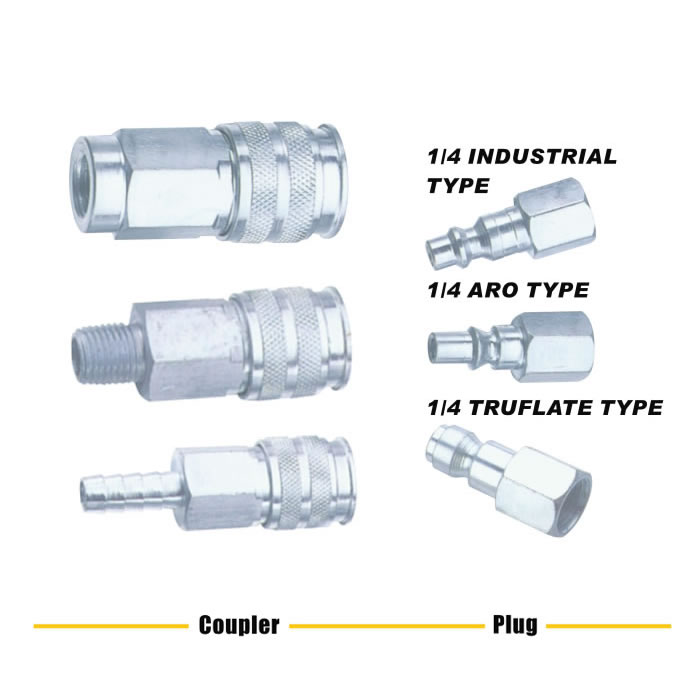

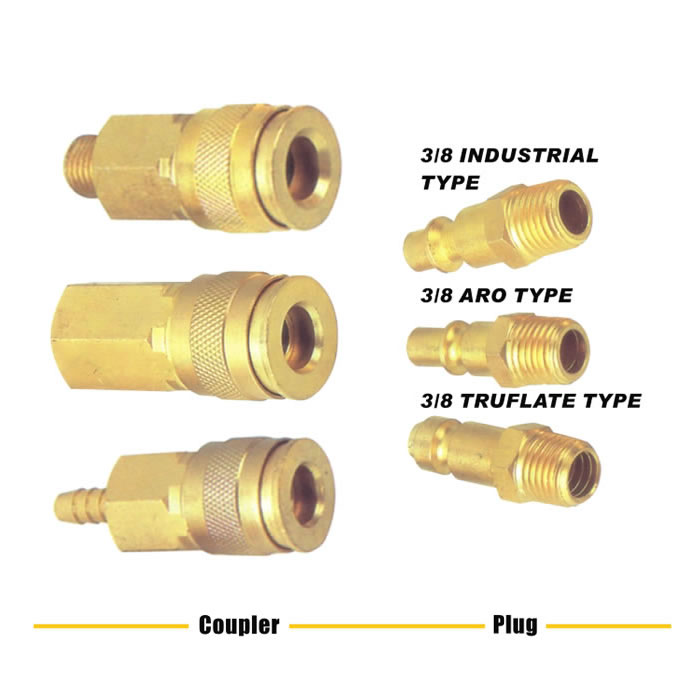

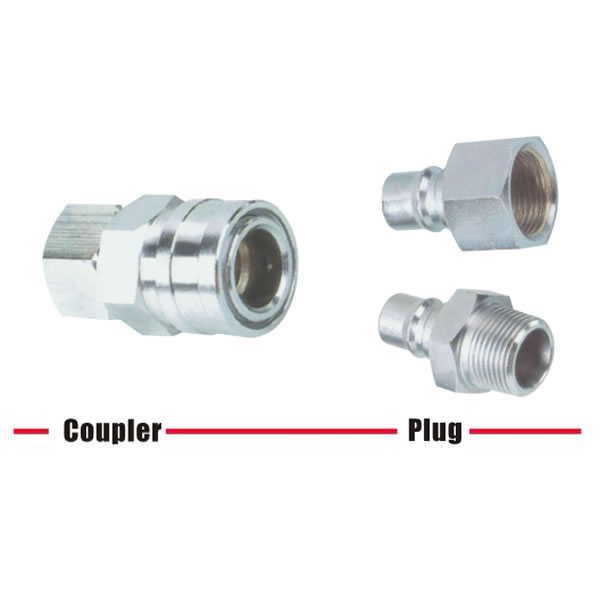

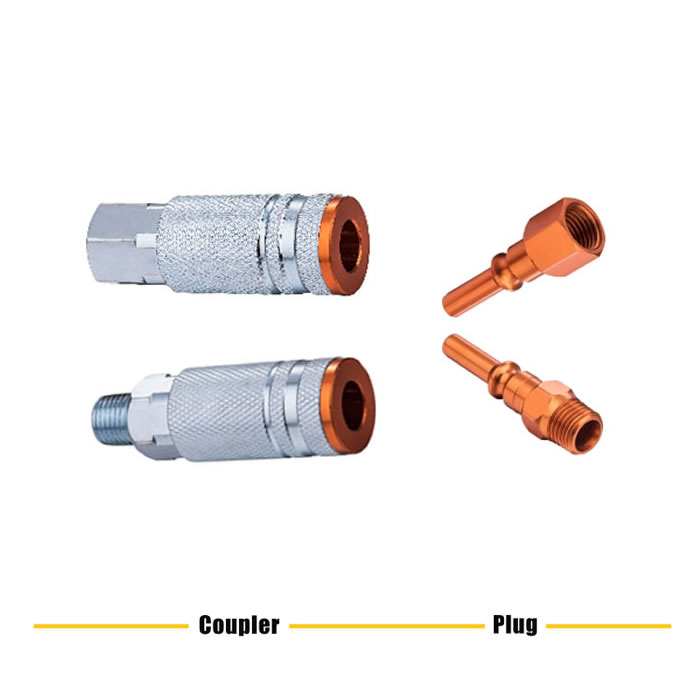

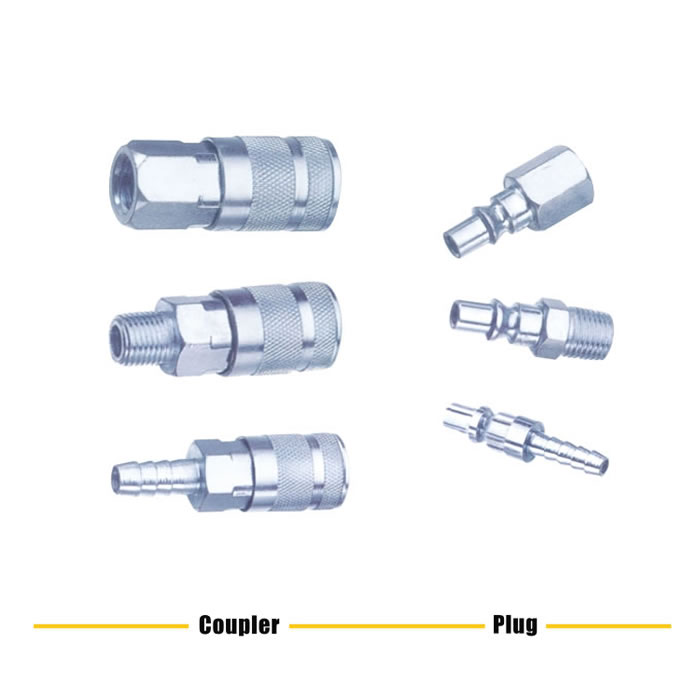

Pneumatic coupler is used to connect compressed air tools to a compressed air line. It allows a tool to be easily connected or disconnected to a hose or pipe while it is under pressure. The system consists of two parts: the quick coupling (the female part) and the plug-in or nipple (the male part) . These couplings are essential for pneumatic systems, ensuring safe and efficient connections for various applications.

Couplers are a type of fitting. So what do they do? Couplers help connect the various components within a fluid transference system. Here, we’re going to focus on pneumatic couplers and how they connect components within a pneumatic system. As with most things fluid transference, there are a lot of different specifications for pneumatic couplers.

LONGWEI offers a wide range of pneumatic quick couplings, available in different materials and industry profiles. They’re commonly used in pneumatic applications but can also be used for other fluid transfer tasks. If you need more information, feel free to ask!

What We Carry

Here at LONGWEI we carry pneumatic couplings for a wide variety of applications in a wide variety of materials, including: plastic, brass steel and PVC. A coupling consists of two parts: one male and one female component. The female part is the piece on the hose or tubing. The male counterpart will be on the tool. Pneumatic couplings are designed so the female part automatically closes the line once a disconnect occurs. This way, no air or pressure is lost.

How do pneumatic couplers work?

Pneumatic couplers are designed to quickly connect and disconnect compressed air tools from a compressed air line, can go by many names, including pneumatic quick disconnect couplings, pneumatic quick disconnect, quick coupler, air coupler and compressor coupling. In a pneumatic system, the coupler connects pneumatic hose or tubing to a pneumatic tools. The coupling is designed to connect and disconnect tools to the line quickly without loss of fluid or pressure.

Quick Coupling: The female part of the coupler, known as the quick coupling, is attached to the air hose or pipe. It has a spring-loaded sleeve that covers the opening.

Plug-In (Nipple): The male part of the coupler, called the plug-in or nipple, is attached to the tool. It has a matching shape to fit into the quick coupling.

Connecting: When you want to connect the tool, insert the nipple into the quick coupling. The spring-loaded sleeve retracts, allowing the two parts to lock together securely.

Disconnecting: To disconnect, push back the sleeve on the quick coupling. This releases the nipple, allowing you to remove the tool without depressurizing the system.

Safety Features: Pneumatic couplers often have safety features to prevent accidental disconnection, such as a locking mechanism or a two-step process for disconnecting.

What are the common sizes for pneumatic couplers?

Pneumatic couplers come in various sizes, and the most common ones include:

1/4" BSP: This size is widely used and has 18 threads per inch with an outside pipe diameter of 0.540 inches.

3/8" NPT: Another common size with 18 threads per inch and an outside pipe diameter of 0.675 inches.

1/2" NPT: Used for larger applications, it has 14 threads per inch and an outside pipe diameter of 0.840 inches.

How do I choose the right size for my specific application?

When selecting the right pneumatic coupler size for your application, consider the following factors:

Flow Rate: Choose a size that can handle the required air flow. Larger couplers allow more air to pass through.

Pressure Rating: Ensure the coupler can handle the maximum pressure in your system. Check the manufacturer’s specifications.

Compatibility: Match the coupler size with the tool’s inlet size. Common sizes are 1/4", 3/8", and 1/2".

Thread Type: Pay attention to thread type (e.g., NPT, BSP). Use compatible threads for a secure fit.

Application: Consider the environment (indoor, outdoor, harsh conditions) and the specific tool you’re connecting.

What are some common applications for quick couplings?

Certainly! Quick couplings find applications in various industries and scenarios. Here are some common uses:

Automotive: Quick couplers connect air tools (such as impact wrenches, air drills) to compressed air lines in auto repair shops.

Manufacturing: Used for pneumatic tools on assembly lines, ensuring efficient production processes.

Construction: Couplings connect air hoses to nail guns, paint sprayers, and other construction tools.

Agriculture: Quick couplings enable easy attachment of pneumatic devices on tractors and farm equipment.

Mining: Couplers connect air-powered tools in mining operations, improving productivity.

Railroads: Used for air brakes and other pneumatic systems on trains.

Aviation: Couplings connect air hoses for aircraft maintenance and repair.

Leave A Comment