Port Fittings – Tapered vs. Parallel Threads

Tech Archives

June 29, 2016

When working with pipe joints, it’s important you first identity the thread sizes and their types as well. It will help you finish up the joints appropriately. Consequently, you can apply the thread sealant in the right manner.

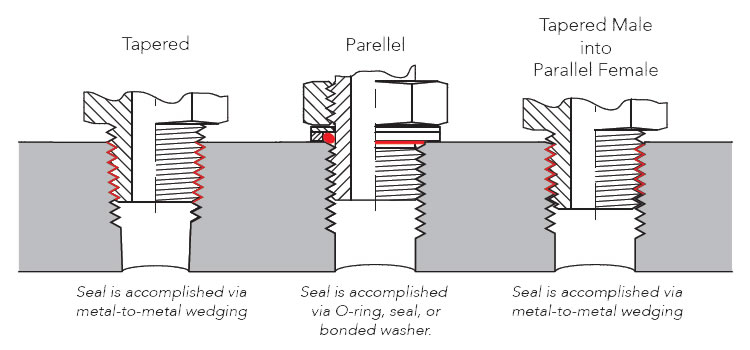

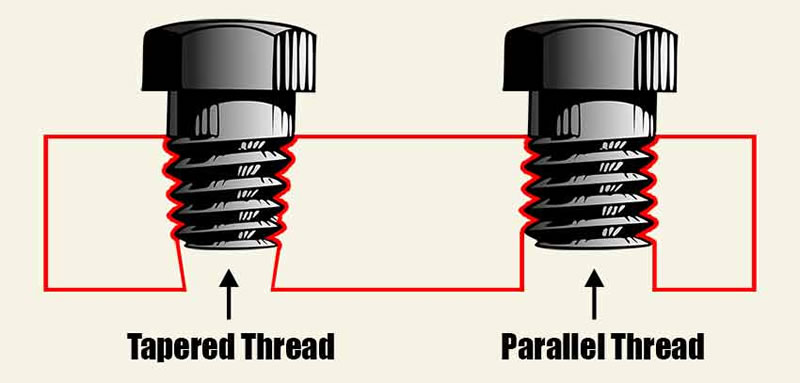

If dealing with a port fitting, the first step towards thread identification is to determine whether the thread is parallel or tapered. Parallel means the thread walls are straight; while tapered means the thread walls, if continued lengthwise, would eventually meet. A seal must be used for all parallel fittings in port application, with the exception of Cutting Face fittings, however these are fairly rare. It is important to note that BSPT (British Standard Pipe – Tapered) can seal into a parallel BSP port, and Metric Tapered threads are capable of sealing into a parallel Metric port.

This first step will help you eliminate a number of possible thread types, as well as possibly reveal the method of sealing. For a parallel thread in port application, the fitting will usually seal at the top of the thread by means of an O-ring or seal. With a tapered thread, the fitting typically seals via metal-to-metal wedging of the threads. A thread sealant is applied prior to installation to reduce instances of leakage on tapered threads.

| Tapered Male X Tapered Female Seals via thread wedging |

Parallel Male X Parallel Female Seals via O-ring/Bonded Seal |

Tapered Male X Parallel Female Seals via thread wedging |

|---|---|---|

| BSPT | BSPP | M-BSPT X F-BSPP (port/fixed female only) |

| Metric Taper | Metric | M-Metric Taper X F-Metric (port/fixed female only) |

| NPT | SAE O-ring Boss |

How to Identify Pipe Thread Size and Type

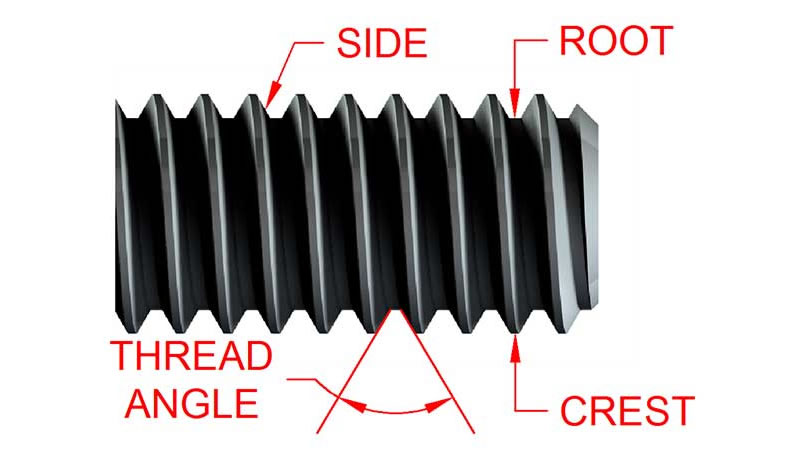

So, what is pipe thread basically? Well first on a pipe end, you will see a spiral design that has peak and valley. It could be either a male or, a female thread. The dimension is related to the number of threads positioned per inch. And so it consists based on the peak and valley of itself.

Hence the peak is referred to as the crest, and the valley is referred to as the root.

And the distance between the two immediate peaks is called the pitch. From the above picture, you can see that there’s an angle lies between two crests. Note that for tapered threads, the diameter size will vary from one end to another. From the endpoint, it gradually increases towards the upper side. Ok… that’s enough of the basics for this moment. Now, let’s explore the steps of determining their diameter and sizes.

Determine Pipe Thread Size

1. Determine the Pitch Size:

You have to calculate the number of threads per inch. That’ll help you find out the pitch size. You can calculate that by using a ruler, but we recommend using a pitch gauge. And that’ll give you accuracy in the result.

So, don’t forget to make use of it, if you have one at your disposal. And you’ll love to see how accurate the measurement is!

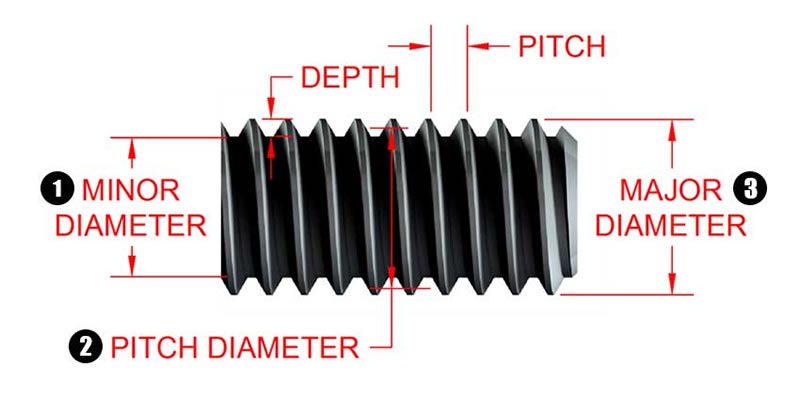

2. Identify the Thread Diameter:

To determine it, you might use a caliper that’s highly recommended. You’d have to measure the outer diameter of a male vs. inner diameter of a female thread. Note the reading of the caliper. There could be 3 types of diameter values for a male thread:

- Minor Diameter

- Pitch Diameter

- Major Diameter

Try to compare it with the specification table (if available).

REMEMBER, if you don’t have a specification and try to compare it with a generalized table, you might observe small variations. The variation occurs due to the production pattern of different manufacturers.

Identify Standard Thread Types: (NPT, PT, BSP-Trimantec)

The different thread types are produced by complying with some rules and guidelines. NPT, PT, BSP, and metric are different standard types. Now, let’s get to know more about each type in a broad sense:

1. NPT thread type:

It’s commonly referred to as National Pipe Taper. NPT is initially designed for water piping applications. NPT correctly handles low-pressure situations. This standard type is widely used in North America. Hence, the thread angle between the pitches is 60 degrees. And that’s both for external and internal angles.

From the name, you have already understood that it’s a tapered thread. NPT has a tapered outer portion and self-sealing inner diameter. If you torqued it, its flanks would compress against each other. This compression will develop a leak-proof seal.

2. BSP Thread type:

BSP is another standard type that’s spelled as BRITISH STANDARD PIPE. It has been used internationally for sealing and joining pipe ends. European countries use BSP standard type. For this type, both the internal and external thread angles are 55 degrees. So the pitches are a bit closer than in the NPT.

BSP is further categorized into two other types: BSPP and BSPT. BSPP has a parallel to straight pipe end structure. BSPT, on the other hand, features a tapered structure. Have you ever heard of G and R pipe end structure types?

We guess you probably had!

BSPP has an alias of G threads, and BSPT is often referred to as R.

3. PT Thread Type:

It is commonly called a JIS tapered pipe thread type. PT is very similar to the BSPT or R. Interestingly, they are interchangeable and compatible.

PT male pipe end doesn’t have a 30⁰ flare.

That’s why it will not be compatible with BSPP female fittings. But you can always create a leak-proof seal using PTFE tape or any sealant compounds at your disposal.

4. Metric tapered Parallel Thread type:

This standard type is most prevalent in Europe. You’ll see it has a cylindrical inner surface. Best force transmission is the flagship feature of metric tapered thread. You will find a mark on this type that says M22 × 1.5.

Hence, the letter “M” stands for Metric type thread and 1.5 indicates the outside diameter. It is highly recommended to use a metric pitch gauge to measure the pitch size.

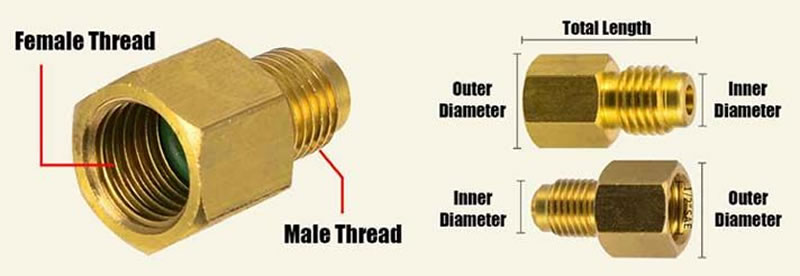

5. Male & Female Pipe Threads:

It is imperative to identify the major types, is it male or female? Observe the location; if it is outside of the fittings, then it’s a male. Alternatively, if it’s located into the inner side of the fittings, that’s a female thread.

6. Tapered vs. Parallel Pipe Thread:

To determine tapered or parallel types, we need to observe their shapes closely. For a tapered pipe end, the seal is done through metal to metal wedging. As for parallel, the seal is made by using an O ring or bounded washer. The second technique is observing the outward extension. If the outward extension narrows down, then you can call it tapered threads. On the contrary, a constant outward extension can be defined as a parallel or, straight type.

Leave A Comment