Quick Connect and Disconnect Couplings

Quick connects and disconnects are couplings — sometimes referred to as couplers, connectors or fittings — meant to improve efficiency and ease-of-use and release in flood handling. Quick coupling are most useful in any application where tubing requires quick and safe connection and disconnection — from biopharmaceutical to food processing.

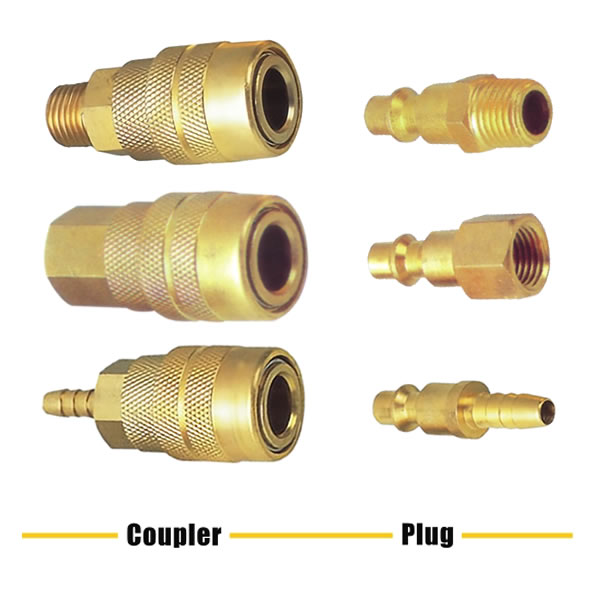

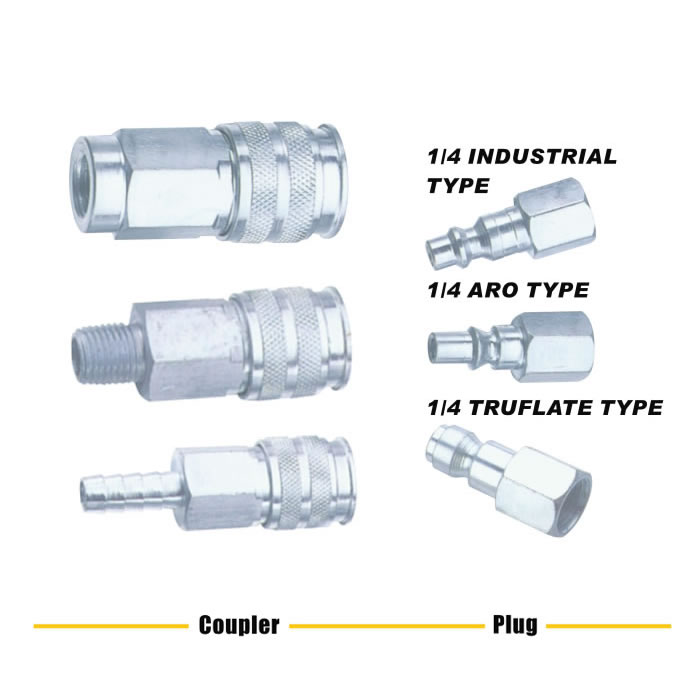

Quick Coupler fittings typically consist of two main parts: a male end and a female end. The male end features a barb or a threaded connector that fits into the socket on the female end. The Quick connect and disconnect coupling most commonly made from carbon steel, stainless steel, brass or plastic, though custom options can be available depending on the type of fluid being handled.

Used in systems that require frequent connection and disconnection like fluid transfer lines, pneumatic tools or hydraulic machinery, these fittings are designed to reduce maintenance downtime and improve safety by minimizing the risk of spills or leaks.

What are the benefits of quick connect and disconnect couplings?

Quick connect and disconnect couplings, also known as quick couplers or quick-release couplings, are mechanical devices used to rapidly connect and disconnect fluid lines or hoses. They find applications in various industries, including hydraulics, pneumatics, automotive, and manufacturing. Quick connects and disconnects can improve the functionality of your equipment and increase the efficiency of your manufacturing process. Other benefits include:

Spill-preventing design: For improved performance and reduced media spillage, quick connect and disconnect couplings from CPC are built with our innovative non-spill technology. Reduced spillage means more reliable protection from chemicals and fumes.

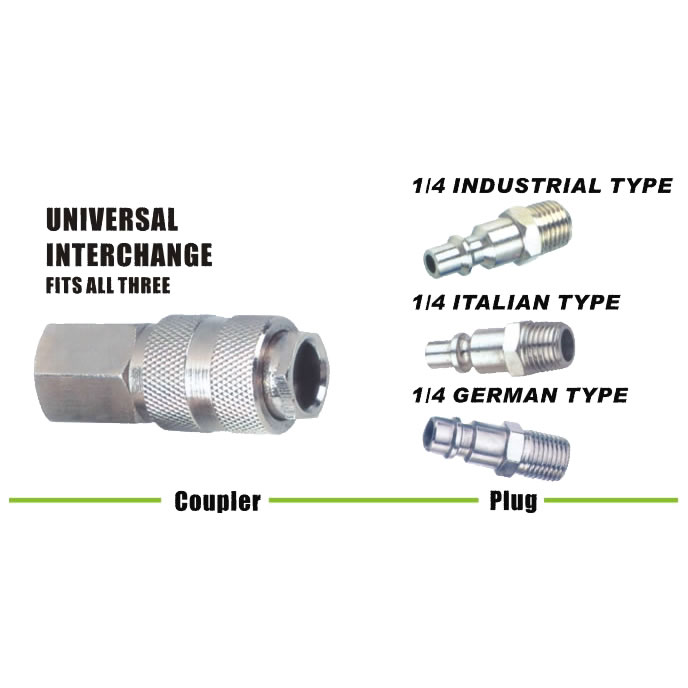

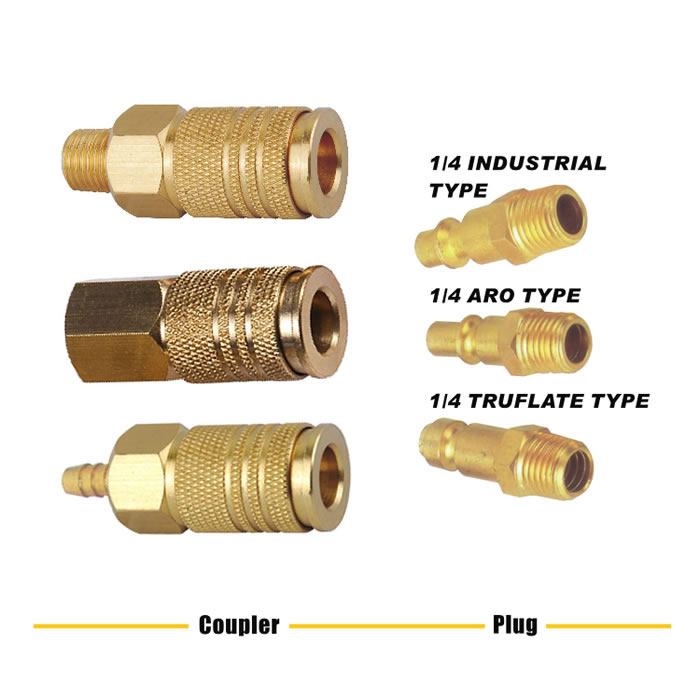

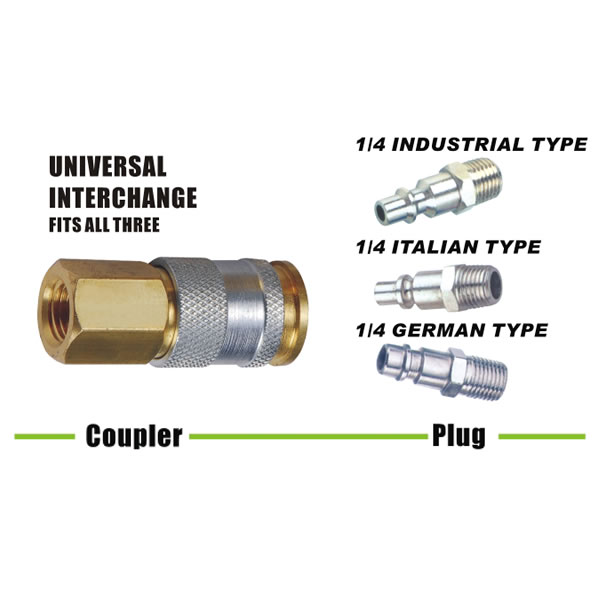

Quick Coupling Types:

Hydraulic Quick Couplings: Used in hydraulic systems to connect hoses, cylinders, and other components.

Pneumatic Quick Couplings: Used in compressed air systems.

Fluid Quick Couplings: Used for liquids such as water, oil, or chemicals.

Quick Coupling Advantages:

Time-Saving: Quick connections reduce assembly and disassembly time during maintenance or equipment changes. Ergonomic designs make it easy to connect and disconnect couplings quickly, even when you’re wearing gloves.

Safety: Quick disconnects should be designed with the aim of eliminating accidental disconnections so that your equipment can operate with optimal efficiency and safety.

Versatility: Available in various materials (e.g., brass, stainless steel, plastic) and sizes.

Automatic Shut-Off: Some designs automatically shut off flow when disconnected.

Quick Coupling Applications:

Industrial Machinery: Connect hoses, tools, and equipment.

Automotive: Fuel lines, air conditioning, brake systems.

Medical Devices: Oxygen lines, IV tubing.

Agriculture: Irrigation systems, pesticide sprayers.

Quick Coupling Considerations:

Pressure Rating: Choose couplings suitable for the system’s pressure.

Material Compatibility: Select materials compatible with the fluid being transferred.

Valved vs. Non-Valved: Valved couplings prevent fluid spillage when disconnected.

What are the different types of quick connects and disconnects?

There are quick connect and disconnect couplings uniquely designed to deliver what is needed for nearly any variety of fluid handling application, including:

Non-Spill. These quick couplers are built using a closed system made to reduce spillage to near zero during disconnection and release.

Valved. Ease the transfer of liquids or gasses through small diameter tubing using these. Configurable in a number of sizes and materials to meet the needs of a wide variety of equipment and devices.

Non-Valved. Non-valved quick connects and disconnects use precise hose barbs to improve the seal and grip when in use with various grades of tubing.

Multiline. These fluid quick connectors help you easily connect two, six or ten separate flow paths within a single coupling. Great for applications where unsightly tubing tangles are a problem.

RFID. Having RFID technology as part of your quick connect or disconnect couplings helps you better track critical information like device type, connected media, line status and other fluid data.

Electrofluidic. These help make the front panel of equipment and devices look cleaner and simplify connections that require power, signal, air or fluids with a single easy-to-use connector.

Drum Connectors. These are a specific type of quick connector that has been designed for applications involving chemical handling, including drums, jerricans and iBC totes.

What are carbon Steel quick couplings

The most commonly used carbon steel quick couplings are extremely tough, and resistant to pressures and tear & wear involved in daily use. NBR is the most popular compound for seals, other compounds can be used depending on the chemical compatibility needed by different fluids. FKM (Viton) in particular allows the quick couplings to have a broad working temperature range and makes them suitable for a wider range of applications. Faster catalog offers the largest selection of Carbon Steel quick couplings, able to answer various market requests and meet specific requirements by different manufacturers and end users.

What are brass quick couplings

Brass quick couplings are resistant to corrosion, durable and strong. This material makes the coupling highly robust and together with FKM (Viton) seals, it makes the couplings able to endure high temperatures. Faster products portfolio includes brass quick disconnects couplings suitable for industrial applications such as refrigeration systems, air conditioning and other applications with refrigerants, mold and die Industry, snubbing units for wells control and others.

What are stainless steel couplings quick release

Stainless Steel quick coupling is necessary when high resistance to corrosion is needed and it offers excellent resilience, for this reason it is often used to make quick couplers for applications characterized by corrosive fluids or harsh environment. Also, the stainless steel quick couplings are equipped with FKM (Viton) seals, thus offering a wider working temperature range, which makes them more versatile and suitable for tougher applications. Even when exposed to potentially corrosive fluids, stainless steel couplings are a guarantee of durability and resistance.