What should you know when specifying quick couplings?

When selecting the right coupling, the frequency of hose connection and disconnection is a major factor in the type of coupler that should be used. For example, at workstations where pneumatic tools are being changed many times throughout a shift, a quick connect coupler allows rapid tool replacement and provides a significant increase in productivity.

Another example is In a fluid power system, if the hose or the tube will be asked to connect and disconnect frequently, such as once a week, then chances are a quick connect coupling will pay for itself rapidly by improving productivity. At the beginning, the quick couplings are precisely engineered for specific fluid applications, as the development of hydraulic system in many industries, Their widespread use over many years has yielded a diverse variety of designs to serve not only specific, but general industrial applications as well.

Many industries are rapidly adopting quick couplings for this very reason, realizing the increase in efficiency far outweighs the increased costs.

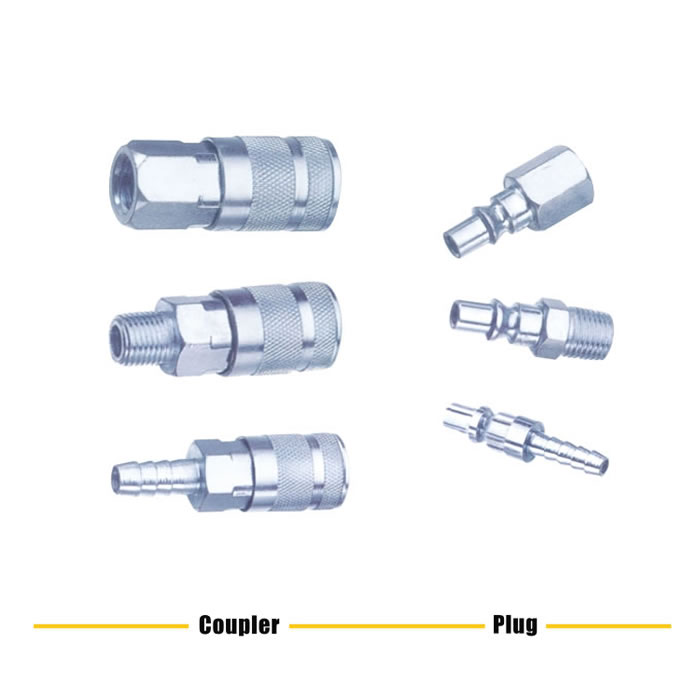

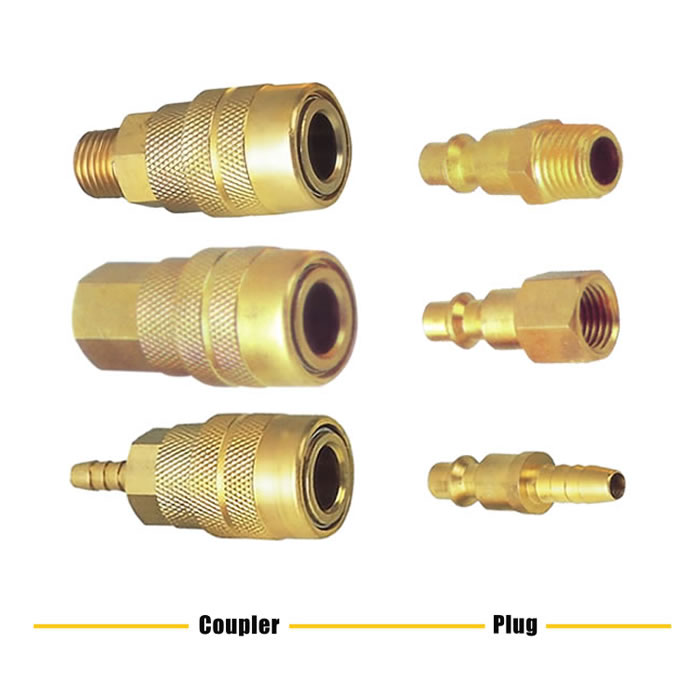

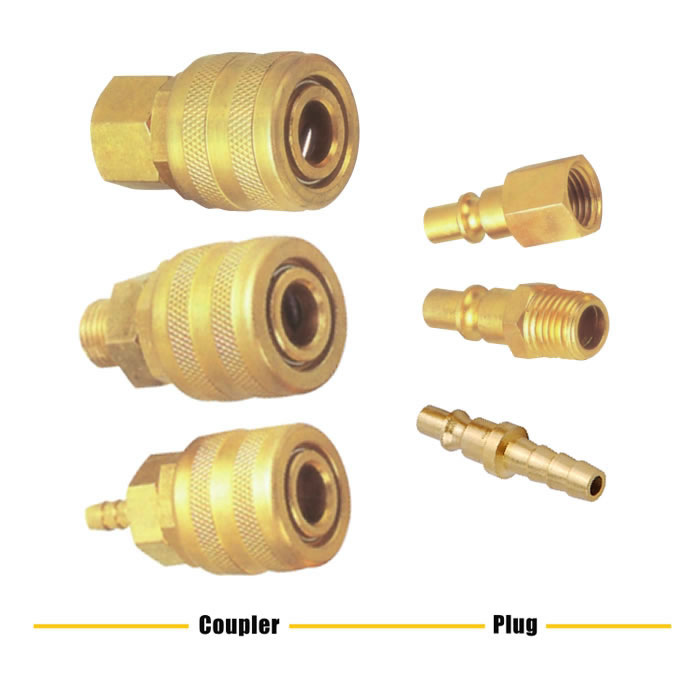

All quick couplings have some elements in common. All have two parts: a plug and a socket. The plug is the male half and the socket is the female half. When connected properly, these parts seal and lock the joint effectively to contain internal pressures and resist any tensile forces that tend to pull the joint apart. The parts are easily disconnected without tools by disengaging a locking mechanism and separating parts.

What is a quick coupling?

A quick coupling, often referred to as a quick coupler, QD or quick-acting coupling, is a mechanical device that provides a fast, easy, sure way to repeatedly connect and disconnect almost any fluid or gas line. They are used in both hydraulic and pneumatic applications, and are designed for easy hand operation for use with fitting attachments primarily on mobile machinery.

Their design is simple: a male end—or plug—is inserted into a female end—or socket—to make a secure, leak-tight seal. They are sometimes called push-to-connect because connecting them requires only a quick push.

They usually feature a one-way sleeve to allow for break-away with a tool when a coupling is clamp mounted. Two-way sleeves allow for one-hand disconnection. In two-way designs, twisting and pulling the two ends breaks the connection. When connected properly, these parts seal and lock the joint effectively to contain internal pressures and resist any tensile forces that tend to pull the joint apart.

These locking seal quick-connect couplings are created by several designs, including:

Ball or bearing type, in which spring-loaded balls lodge in cavities to make the connection. This is the most common type, because they can be disconnected with just one hand.

The most significant advantages of a quick couplings over standard hydraulic connections are:

Time of connection/disconnection

Prevention of fluid leakage

Where are quick coupling used?

The more frequently hoses must be connected and disconnected, the more valuable quick couplings become. They also become more critical as machine productivity increases.

One common application is hydraulic test, if you need to connect the hydraulic test to the product by thread, it will take lots of time to connect and disconnect, use quick couplings, Just a quick push/pull, and the assembly is ready to test.

Choosing the right coupler for the job

Before selecting a coupling, important questions must be answered regarding performance:

> What are the functional requirements of the coupling?

> What is the maximum working pressure of the application?

> Which seals and body material are compatible with the system’s fluid?

> Is the application static or dynamic?

> What size coupler/hose is required?

> What is the maximum pressure drop suitable for the application?

> Does the application require the ability to connect and disconnect under pressure?

> What is the media temperature and ambient temperature?

> What end configurations are required?

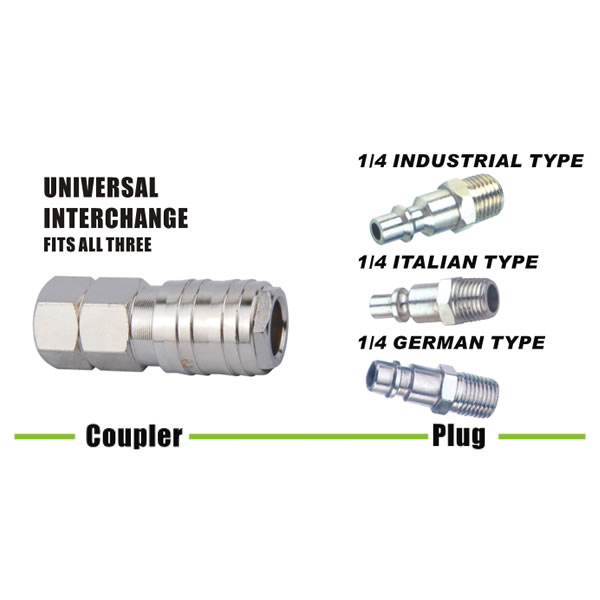

> Is an industry interchange coupler required?

> Are air inclusion and fluid loss concern in the application?

Once these questions have been answered, a preliminary selection of coupling type can be made: one, two or no shutoff valves, and the type of connecting and disconnect mechanism. Keep in mind that one style may offer the greatest convenience in service, but a different model's lower pressure drop may be more desirable for the application.

how to choose quick couplings for your applicatoins?

1.Connection Mechanism

There are kinds of connection mechanisms that designed for different condition, to choose an effective and safe connect mechanism is very important. Common types of connections include ball and sleeve, push to connect,With a ball and sleeve coupling, the user simply needs to pull back the female sleeve from the male ball to connect or disconnect the coupler.Push-to-connect couplings allow you to push either end into the other to connect, while luer fittings require the operator to twist the coupling. Cam-lock couplings come with connectors that fold down to connect the application.

The machine manufacturers will always choose the quick coupling with a suitable connection mechanism, that make the machine work safely and efficient. The most popular connection mechanism is ball locked, push to connect. That is why the ISO 7241 (both A and B) a developed by this connection Mechanism.

2. The valve option

The quick coupling are working for a the hydraulic or other liquid circuit, it can help the circuit connect and disconnect to make people easy to change some parts. That the valve is important to prevent the liquid leak. There are type of valve, Ball valve, Poppet, and flat face. The ball valve that prevent the liquid leak by the ball were pushed to the connect hole that the material deformation to prevent the liquid leak. The poppet and flat face will use seal ring to prevent the leak.

Comparing the valve that use seal materials, the ball valve is usually used for some high pressure applications that because the ball valve can work at a very high temperature, but disadvantage is that the ball valve easy to be damaged by the impurities in the hydraulic oil or some other impurities. Use the seal rings, we have to pay attention the material of the seal that because they are different performance on different temperature or different liquid materials.

3. Seal Materials

1,Nitrile (NBR) Buna-N & Low-Temp

Temperature range: Buna-N between -40°C and +135°C (intermittent up to +150°C); Low-Temp between -65°C and +120°C

Applications: Nitrile (NBR) is currently the most extensively used elastomer in the Fluid Seal Industry. Furthermore, Nitrile oil seals incorporate exquisite reluctance to hydraulic oils, water, silicone greases, petroleum-based oils and fluids, and alcohols. Nitrile presents great stability of working attributes such as high tensile strength, high abrasion resistance, and low compression set combined with low cost.

Resistant to: Water, Petroleum Oils & Fluids, Hydraulic Oils

2,Viton® (Fluoropolymer FKM)

Temperature range: between -20°C and +205°C or between -45°C and +230°C (intermittent/compound-specific)

Applications: FKM Fluorocarbon oil seals distinguish a great resistance to solvents and petroleum oils. They are, therefore, great for high-temperature installations and have present low compression set attributes. Additionally, they are adapted for use with large chemical exposure and hard vacuum applications.

Resistant to: Transmission Fluids, Gasoline, Petroleum Oils

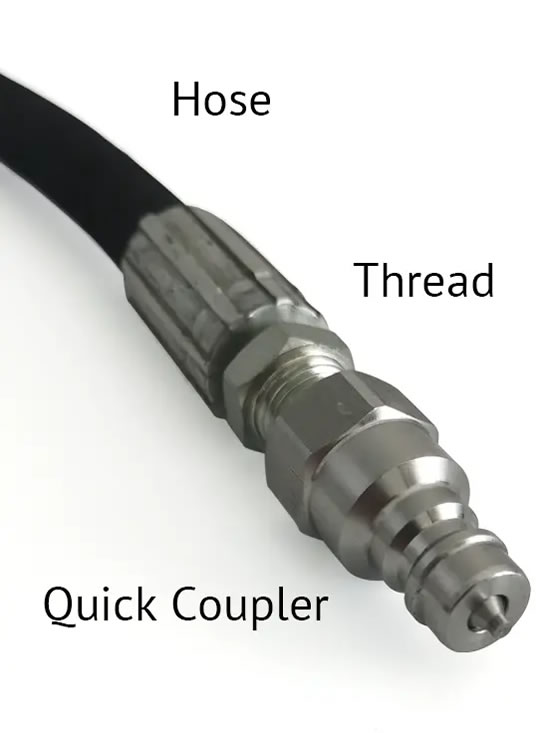

4. Pipe Thread

Thread is the most important thing is for personal user, because quick couplings are usually used on the equipments, they need to connect to other components like fittings and hydarulic tubes, if the customer bought the wrong thread, it cannot work for his applications. Different countries use the very different thread and because of some countries will import equipment countries, in their marketing, all threads are covered.

National Pipe Thread Tapered (NPT) is a U.S. standard for tapered threads used to join pipes and fittings. ANSI/ASME standard B1.20.1 covers threads of 60-degree form with flat crests and roots in sizes from 1/16 inch to 24 inch Nominal Pipe Size [NPS]

There is also a semi-compatible variant called National Pipe Thread Tapered Fine (NPTF) also called Dryseal American National Standard Taper Pipe Thread, defined by ANSI B1.20.3, designed to provide a more leak-free seal without the use of teflon tape or other sealant compound.

British Standard Pipe (BSP) threads are used commonly in many countries outside the U.S. The most common BSP threaded fittings are tapered with pressure tight joints achieved by the threads.

The ISO metric screw threads are the most commonly used type of general-purpose screw thread worldwide. They were one of the first international standards agreed when the International Organization for Standardization (ISO) was set up in 1947.

5. Pressure

The Pressure is the last one but the most important thing we need to think about for the applications. Don’t use the normal pressure quick couplings on the high pressure equipments, it is very dangerous.

usually, the normal quick coupling can work at a 3000-4500 PSI, that as the currently tech, that most of the quick couplings can work well. 10000 PSI is a important line to choose a higher requirements on the quick coupling types or designs.