What are Ball Valves?

Ball valves are quarter-turn valves that use a hollow, perforated, and pivoting ball to control the flow of materials from one opening to the next. The valve can be open, closed, or partially open to allow gasses, liquids, and slurry materials pass through it. Ball valves are used in applications where tight shut-off is required.

Ball valves are extremely versatile as they can handle pressures up to 1000 bars and temperatures up to 400 degrees. Their sizes range from 0.5 cm to 121 cm and they are easy to operate and repair. Ball valves are designed to allow only a 90-degree rotation for opening and closing the valve. This means the valve locks fully when the handle is turned. Ball valves are popular in industrial use because of the air-tight seal they provide when fully closed.

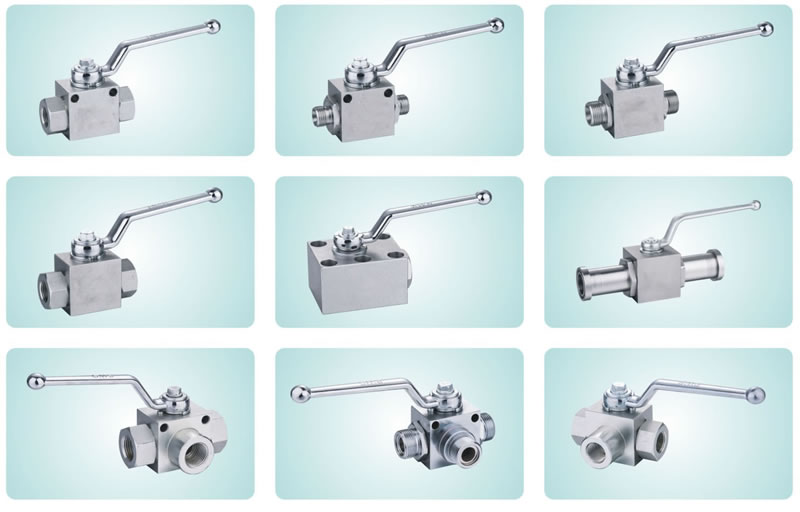

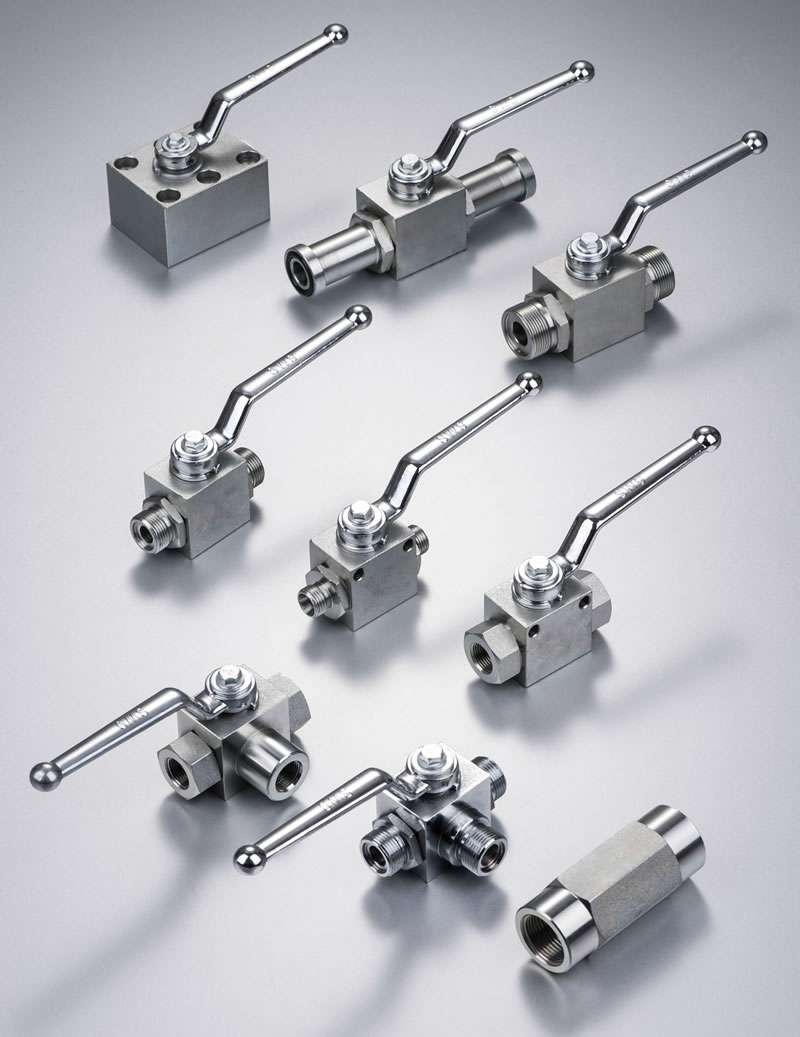

High Pressure Ball Valve

KHB,KHM Series High Pressure Ball Valve

KHB3K Two-position Three-way High Pressure Ball Valve

KHB,KHB3K Ball Valve Aside Mounting Holes Series

VH2V Series Straight High Pressure Ball Valve

VH3V Series of Two-way High Pressure Ball Valve

SAE Flange Ball Valve

KHB-F3/6,KHM-F3/6 Series SAE Flange Hydraulic Valves

KHP/KHP3K Manifold Mounted Ball Valves

BKH(MKH)-SAE-FS Series High Pressure Ball Valve

About Ball Valves

Chosen for their durability and reliability, ball valves provide on/off control for fluid or gas media. Ball valves appear in many industrial and commercial processing systems, and there are product variations that can accommodate almost any application. Several of these variations involve the number of pieces that make up the valve body design, which affects the upfront cost and capacity for maintenance.

Ball Valve Types

Standard (threaded) Ball Valves

Standard ball valves consist of the housing, seats, ball and lever for ball rotation. They include valves with two, three and four ports which can be female or male threaded or a combination of those. Threaded valves are most common and come in many varieties: with approvals for specific media or applications, mini ball valves, angled ball valves, with an integrated strainer or a bleed point and the list goes on. They have a wide range of options and a large operating range for pressure and temperature.

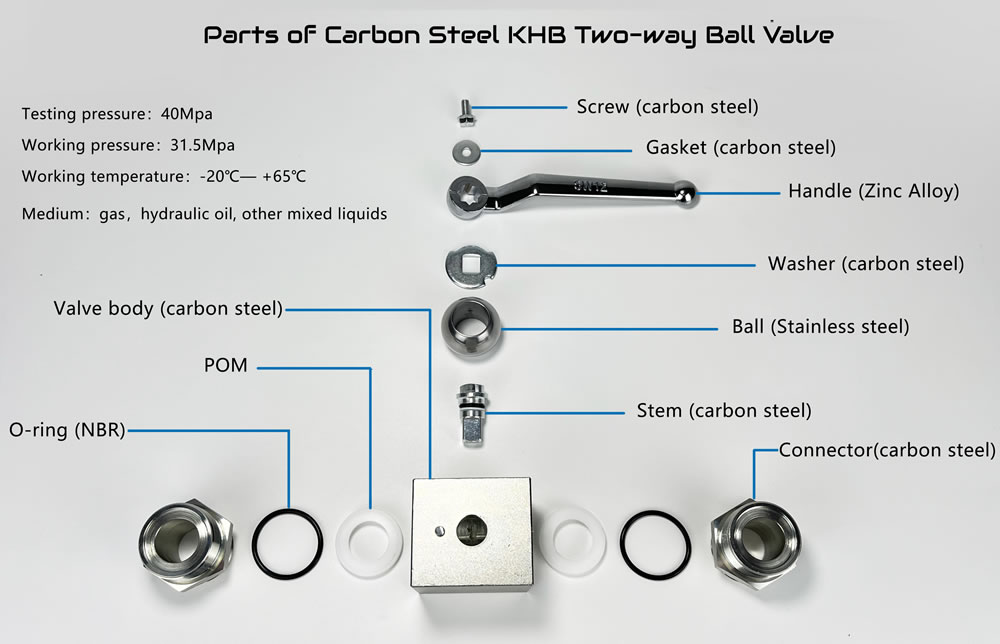

Hydraulic Ball Valves

Hydraulic ball valves are specially designed for hydraulic and heating systems due to their high operating pressure rating and hydraulic and heating oil resistance. These valves are made of either steel or stainless steel. Besides these materials, the seats also make hydraulic valves suitable for high operating pressure. The seats of these valves are made of polyoxymethylene (POM), which is suitable for high pressure and low temperature applications. The maximum operating pressure of hydraulic ball valves goes above 500 bar while the maximum temperature goes up to 80°C.

Flanged Ball Valves

Flanged ball valves are characterized by their connection type. The ports are connected to a piping system via flanges that are usually designed in accordance with a certain standard. These valves provide a high flow rate since they typically have a full-bore design. When choosing a flanged ball valve, besides the pressure rating, you also have to check the flange compression class which indicates the highest pressure this connection type can withstand. These ball valves are designed with two, three or four ports, they can be approved for specific media. They are typically made out of stainless steel, steel, or cast iron.

Vented Ball Valves

Vented ball valves look almost the same as the standard 2-way ball valves when it comes to their design. The main difference is that the outlet port vents to the environment in closed position. This is achieved by a small hole that is drilled in the ball and in the valve body. When the valve closes, the holes line up with the outlet port and release the pressure. This is especially useful in compressed air systems where depressurization provides a safer working environment. Intuitively these valves look like 2-way ball valves while in fact they are 3/2-way due to the small borehole for venting.

View our ball valves selection here!

One vs. Two vs. Three-Piece Ball Valves: Construction & Applications

What is a One-Piece Ball Valve?

This is the cheapest ball valve because it features a single piece of housing that is welded or forged to the body of the valve. One-piece ball valves cannot be opened so cleaning, maintenance, or replacement of parts is impossible. This ball valve is suitable for small scale industrial applications and materials like gases that do not require valve maintenance.

A 1-piece ball valve consists of a single, solid body with two openings, threads for screw-in connection and a manual handle or actuator for operation. They are compact, economical, lightweight and reliable, since they present few opportunities for leakage.

One-piece ball valves are typically offered only in reduced port sizes, meaning the port size of the ball valve is smaller than that of the pipe size. For applications where flow rate is a critical consideration, 1-piece ball valves may not be the best choice.

What is a Two-Piece Ball Valve?

This ball valve is made of two pieces of housing that are threaded together. Two-piece valves can be disassembled for cleaning and maintenance but that requires the valve to be disengaged from the pipeline.

Two-piece ball valves feature a main body with a single threaded end connection and a lever. They are also available with a bolt and flange connection assembly, as well as with larger port sizes.

Like One-piece ball valves, Two-piece ball valves are not designed to be repaired, since removing them once they are screwed in can cause galling on the threads (wear due to adhesion). Furthermore, the NPT connection is designed to be screwed in once and properly torqued to create a metal-to-metal seal within the valve body. Unscrewing this connection disrupts this seal and is not recommended.

Two-piece ball valves provide bidirectional flow shutoff and are available in full port configurations for applications where flow rate is critical. They are compact, reliable and economical, if slightly more expensive to replace than 1-piece ball valves.

When to Use 1-Piece & 2-Piece Ball Valves

One- and 2-piece ball valves are the most common types of ball valves used across industries, wherever on/off fluid control is required. An exhaustive list of applications would be pages long, but common use cases include processing plants in the food, automotive, chemical, pharmaceutical and agricultural industries.

While either type of ball valve is adequate for many applications, neither 1- nor 2-piece ball valves should be used in high-cycle or high-pressure systems that require frequent maintenance. One-piece ball valves are not designed to be repaired, and, while it is possible, attempting to repair and reinstall a 2-piece ball valve is not recommended.

What is a Three-Piece Ball Valve?

Three-piece ball valve features three different pieces of housing that are bolted together. The valve can be easily cleaned and maintained. The internal parts can also be replaced without disengaging the valve from the pipeline. Three-piece ball valves are more expensive than the other two types of valves in this category.

A 3-piece ball valve consists of a main body and two pipe connectors, one at each port. The connectors are typically either threaded, welded or flanged to a pipe, which allows only the valve body to be removed for cleaning and repairs. Both metal and elastomeric components can be easily replaced, including the ball, ball seat, stem and seals.

While three-piece ball valves carry a higher cost up front than those with fewer pieces, they are often the more cost-effective option in the long term. They can remain in service for their intended lifespan, sometimes longer, and replacing the components is far less expensive than replacing the entire valve. Additionally, the ability for the connectors to remain in place during maintenance prevents a line shutdown, so production can continue as needed.

Three-piece ball valves are available with full port and standard port options and are favored for applications in which frequent maintenance is necessary.

When to Use a 3-Piece Ball Valve

When properly maintained, the 3-piece ball valve is the most durable option of these product variations. The 3-piece ball valve is ideal for high-cycle, high-pressure applications that experience a great deal of wear and tear. Most notably, 3-piece ball valves offer the ability to remove components for cleaning or repairs, sometimes while the valve body is still in place. This means that easily worn elastomeric components like seals can be changed or replaced based on changing system conditions or age.

Three-piece ball valves are available with multiple connection types, including Female National Pipe Taper (FNPT), socket weld and tube socket weld.

One-Piece, Two-Piece & Three-Piece Ball Valve Comparison

| 1-Piece Ball Valves | 2-Piece Ball Valves | 3-Piece Ball Valves | |

| Benefits | ☆ Most economical option ☆ Can be replaced at a low cost |

☆ More economical than 3-piece ball valves ☆ Available in full port |

☆ Easy to disassemble for maintenance ☆ Long-term cost savings for high-cycle or extreme applications ☆ Available in full port ☆ Connection options include FNPT, socket weld and tube socket weld |

| Drawbacks | ☆ Not designed to be repaired ☆ Full port options not available |

☆ Not designed to be repaired | ☆ Higher cost up front |

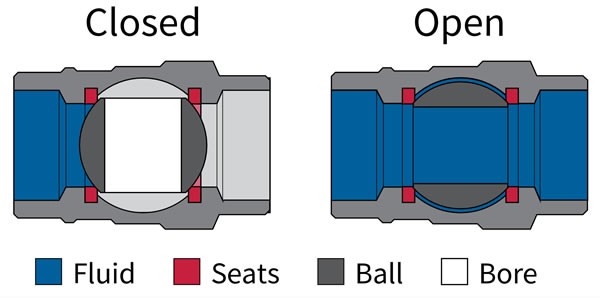

How Does a Ball Valve Work?

Ball valves are shut-off valves that use a ball to start or stop the flow of materials through the valve. The ball in the valve performs the same function as the disc in other valves. The ball is hollow and features a hole that is also known as the bore. When the actuator is moved, the ball rotates to a point where part or the entire bore is in line with the valve body inlet and outlet. This allows the materials to flow through the valve.

Ball valves can have multiple ports, which are the openings in the valve. Two-way ball valves have two ports and are used for traditional on/off control. Multi-port valves (3-way, 4-way, etc.) are used in applications that require more than one source of media or that need to divert media in different directions.

To close the valve, the actuator is moved again. The ball rotates to a point where the bore is perpendicular to the flow path. This causes the flow to stop. Most ball valves require a 90-degree turn of the actuator to fully open or close. The valve can be partially opened but that causes damage to the ball valve. This is the reason why ball valves do not belong to valves recommended for throttle applications. They are most suitable for applications where tight shutoff is necessary for example to control the flow of gas.

Ball valves can be unidirectional, bidirectional, or multidirectional depending on the number of valve seats and ports. For example, a two-way ball valve with a single seat will be unidirectional with flow direction indicated on the valve. The same valve with two seats will be bidirectional. In this valve, one seat will be on the upstream side while the other will be on the downstream side of the ball. Three-way, four-way, and five-way multiport ball valves can be unidirectional if the flow is entering through a designated port. Ball valves with multiple ports allow flow in more than one direction eliminating the need for several valves.

Ball valve working principle

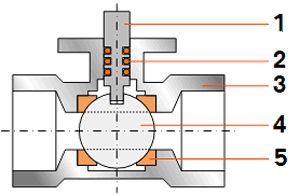

Ball valve diagram

To understand the working principle of a ball valve, it is important to know the 5 main ball valve parts and 2 different operation types.

The valve stem (1) is connected to the ball (4) and is either manually operated or automatically operated (electrically or pneumatically).

The ball is supported and sealed by the ball valve seat (5) and their are o-rings (2) around the valve stem.

All are inside the valve housing (3). The ball has a bore through it. When the valve stem is turned a quarter-turn the bore is either open to the flow allowing media to flow through or closed to prevent media flow.

The valves circuit function, housing assembly, ball design, and operation types all impact the ball valves operation are are discussed below.

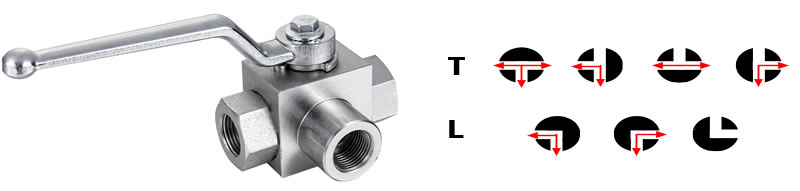

Ball Valves Circuit function

The ball valve may have two, three or even four ports (2-way, 3-way or 4-way). The vast majority of ball valves are 2-way and manually operated with a lever. The lever is in line with pipe when the valve is opened. In closed position, the handle is perpendicular to the pipe. The ball valve flow direction is simply from the input to the output for a 2-way valve. Manually operated ball valves can be quickly closed and therefore there is a risk of water hammer with fast-flowing media. Some ball valves are fitted with a transmission. The 3-way valves have an L-shaped or T-shaped bore, which affect the circuit function (flow direction). This can be seen in Figure 3. As a result, various circuit functions can be achieved such as distributing or mixing flows.

Benefits of Ball Valves

Compared to other types of valves, ball valve offer several notable advantages:

☆ Compact, economical designs

☆ Fast shut-off speeds

☆ Durable in high-pressure, high-volume and high-temperature applications

☆ Less prone to corrosion or damage

☆ Long service life

☆ Versatile and ideal for a range of industrial applications

What are the Applications of Ball Valves?

Ball valves provide reliable leak protection which makes them perfect for a number of industrial applications. They have a low-pressure drop and can open and close quickly which makes them great for liquid and gas applications. Ball valves are extremely versatile so they can be used for subsea, underground, and cryogenic services.

Ball valves can be used for air, gas, and liquid applications that require bubble-tight service. They can also be used in low-point drains and high-point vents for liquid, gas, and other fluid applications. Cooling water and feed water systems can be regulated using ball valves and they can also be used for steam services.

Ball valves can be used at turbine skids, gas feed lines, compressor skids, crude oil plants, generator skids, polymer plants, separator skids, LNG plants, field gas plants, industrial gas processing plants, tank farms, oil refinery feedstock lines, hydrocarbon processing, and automated process applications. Stainless steel ball valves can be used in petroleum refining, desalination, and brewing.

Here’s a look at a few examples:

Home applications:

☆ Washing Machines

☆ Outdoor Hoses

☆ Dishwashers

☆ Specialized industries:

Oil & Gas

☆ Food & Beverage Equipment

☆ Automotive

☆ Vehicle Wash Systems

☆ Power Processing

☆ Pharmaceutical

☆ Chemical Admixtures & Treatment

☆ Irrigation & Water Treatment Equipment

☆ Manufacturing Facilities

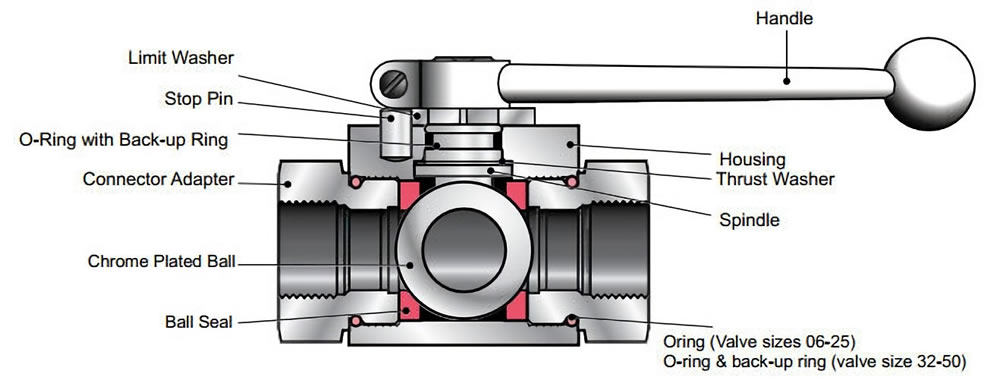

Parts of a Ball Valve

Ball valves are constructed with several crucial components:

Valve Body

This is the main part of the valve and contains all of the components for on/off control.

Rotary Ball

The ball is designed with a center bore (hole) that the media flows through. The direction of the ball is controlled by turning the stem.

Stem

This connects the ball to the external control mechanism. For example, in a manual ball valve the stem is connected to a handle or lever.

Seats

These are discs that lie in between the body and the ball. Seats provide a seal between the two and also support the ball.

Power Source

The stem of the ball valve is rotated using manual or actuated power sources. Manual actuation includes levers and handles that are controlled by an operator. Automated power sources like electric, pneumatic and hydraulic actuation are also available.

Packing

This is a seal around the stem that prevents the media from escaping.

Bonnet

The bonnet is the part of the body that contains the stem and packing.