Plastic Packaging

ingbo Haishu HuaDing Plastic Hardware Factory established in 2004 located in Ningbo City, China. is a professional manufacturer engaged in the research, development, production, sale, and service of Plastic Blister Packaging.

Specialized in the production of plastic blister packaging products for a wide variety of Hardware, Household, Electronics, Toys, food & Medical packaging. And we use various food-grade raw materials such as APET, RPET, CPET, PETG, PP, PP/PE, PS, OPS, and PVC.

HuaDing provides a whole industry chain manufacturing and a series kinds of Plastic Packaging services, including product design, mold tooling design, manufacturing, warehouse logistics, and other after-sales service. HuaDing also welcomes OEM and ODM orders. OEM products are indirectly supplied to world-renowned customers.

What we offer

Custom Plastic Blister Packaging / TOGO Food Containers

What is plastic blister packaging?

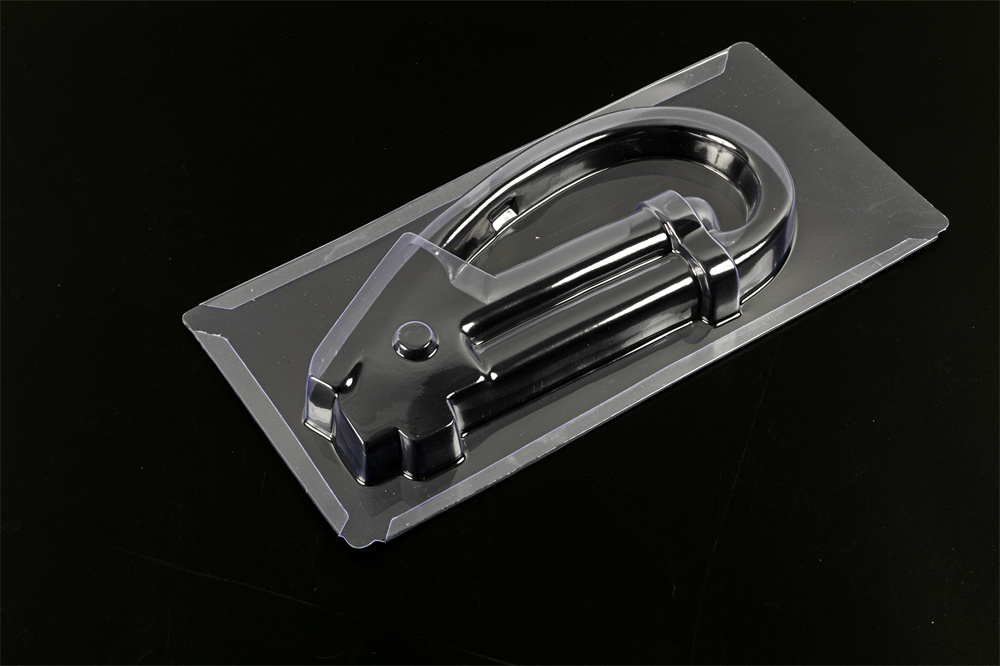

Blister packaging is a type of packaging produced by heating a sheet of plastic and moulding it into shape to form a bubble or pocket the ‘blister’ that completely covers the product.

A traditional blister pack is known as a face seal blister and has a cardboard back. The plastic blister is fixed to the front of the cardboard, to contain and protect the product. You can read more about the different types of blister packaging below.

The blister can be made in any shape a uniform shape to protect tablets, for example, or an unusual shape to protect a less consistently shaped product, like the football figurines shown in the image below.

blister package is one of the most popular methods to retail a product because it is visible behind a glossy covering and gives the consumer a full view of your product while protecting it from dirt, moisture, and theft.

Use the blister card as a “billboard” to communicate your message about the product’s use and features. Choosing the correct size blister card allows you to describe your product in detail while attracting the consumer with colorful and “catchy” graphics.

What We Do for the Plastic Packaging

Food Storage Containers

We know meal prepping is a game changer when it comes to saving time in the kitchen. Keep your premade meals organised and fresh with our food storage solutions.

The meal prep sets have been designed specifically for multifunctionality. Microwave, dishwasher, freezer and oven-safe, they’re ideal for meal prep, food storage and eating on-the-go. 100% leak proof and airtight, they give you peace of mind and keep your food fresher for longer.

Take your meal prep game to the next level with these durable meal prep containers. Available in 1-compartment, 2-compartment, and 3-compartment options with various colors to fit your style.

Customized Colorful Food Containers Lid

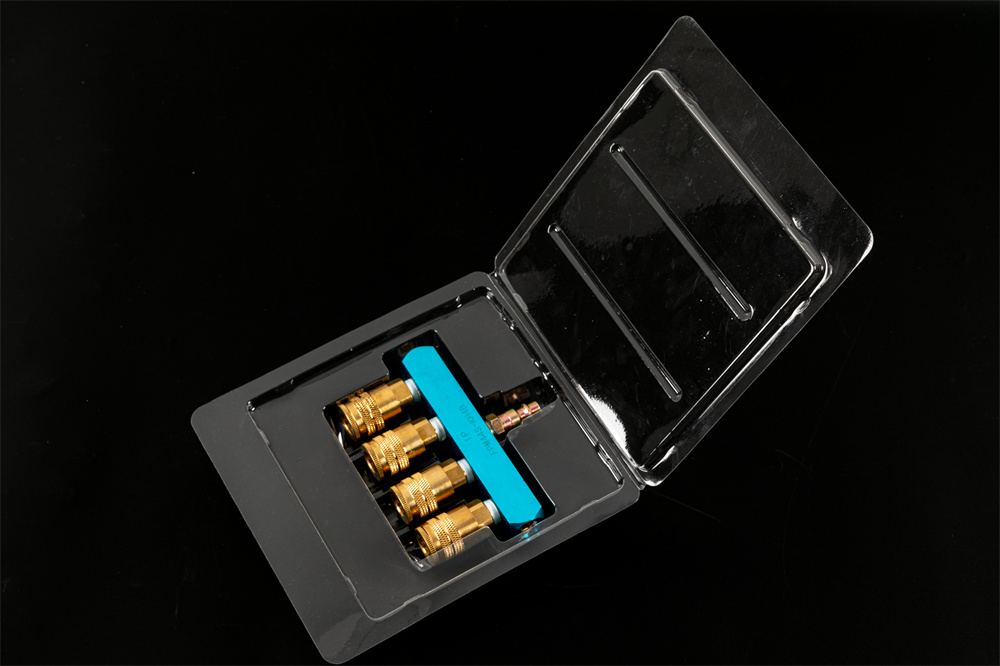

Clamshell blister packaging is a type of packaging that is used to securely hold and display products. It typically consists of a clear plastic blister that is sealed to a cardboard or plastic backing card. The blister is formed by heating a piece of plastic and then shaping it around the product, while the backing card provides stability and support.

Clamshell blister packaging is commonly used for small consumer goods such as toys, electronic devices, and tools. It provides an easy way for customers to see the product and provides a secure package that is difficult to open without damaging the packaging, which can help to deter theft.

Clamshell Blister Packaging

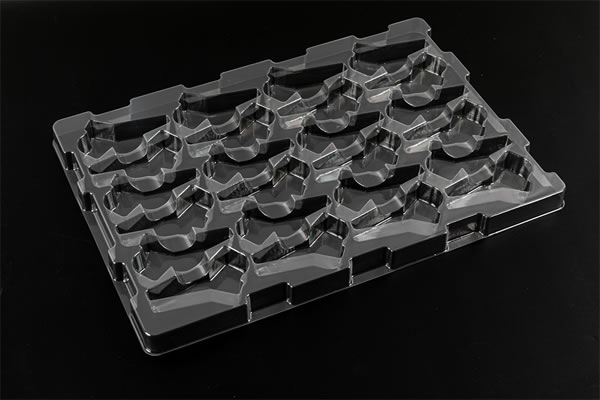

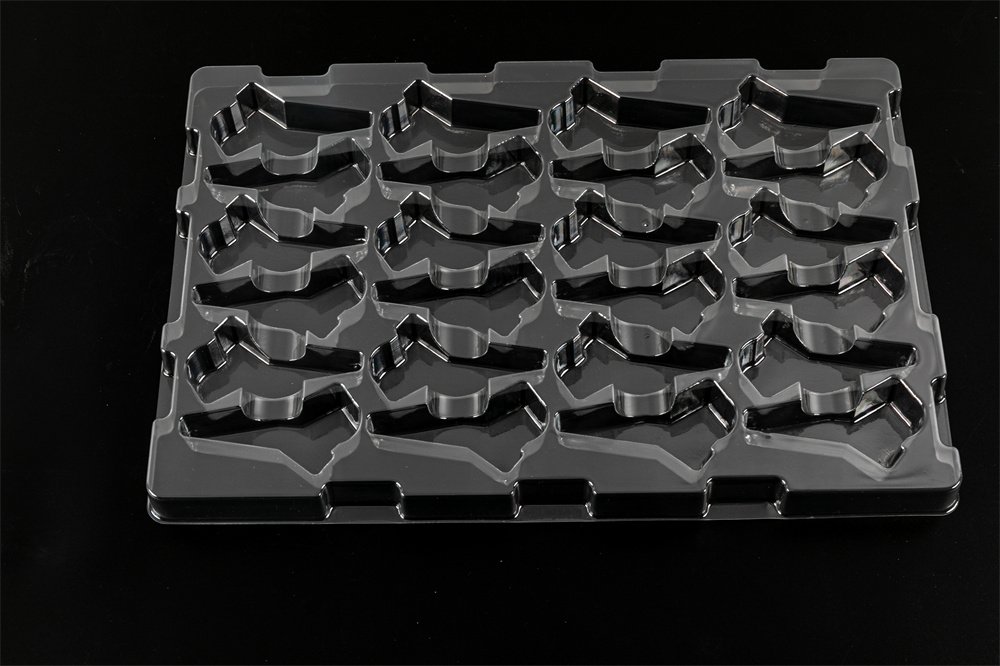

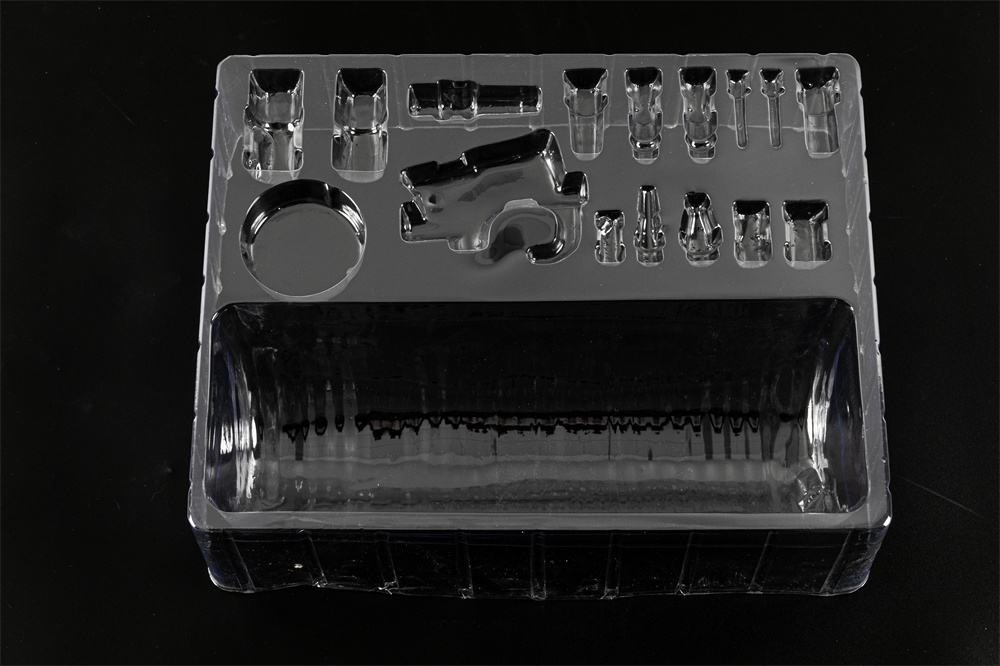

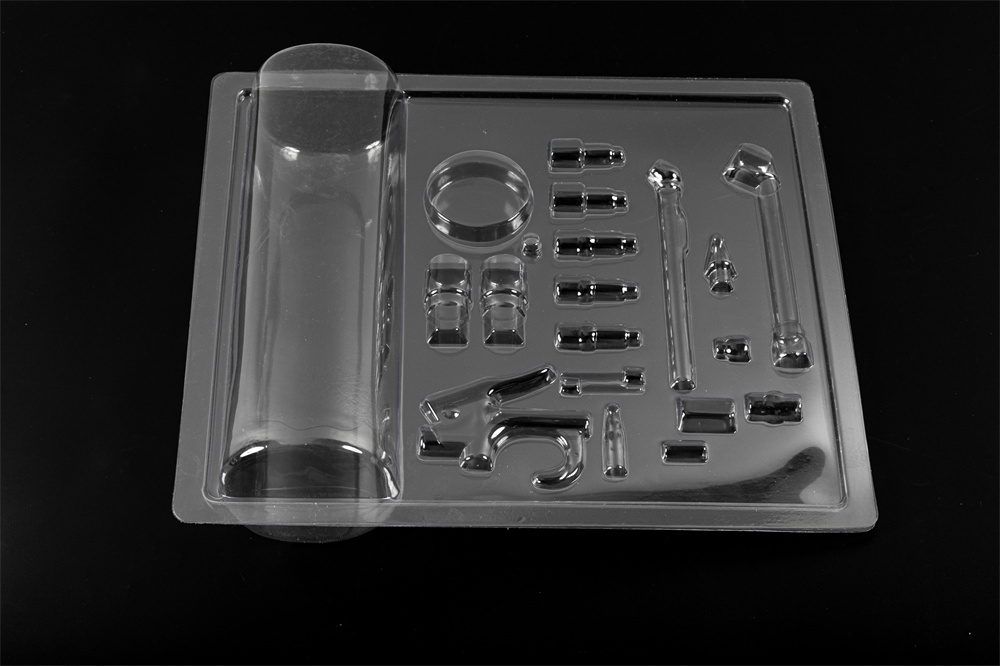

Thermoformed Blister Trays

Blister tray packaging is a type of packaging that uses a clear plastic blister that is formed around a product and is then sealed to a card or paperboard backing. This type of packaging is commonly used for consumer goods such as small toys, hardware items, and small electronics. The clear plastic blister allows the product to be easily seen, and the card or paperboard backing provides a sturdy surface for the product to sit on.

Blister tray packaging is also often used for items that are sold in sets, such as tools or small parts, as the blister can be used to hold multiple items in a single package.

Slide blister packaging is a type of packaging that uses a blister, or raised area on the surface of a card or plastic sheet, to hold a product securely in place. The product is usually visible through a clear plastic blister, which is sealed to the card or plastic sheet with a heat seal.

Slide Card Blister Packaging is commonly used for small consumer goods such as pills, toys, and small electronics. It provides a cost-effective and visually appealing way to package and display products.

Slide Card Blister Packaging

Double Blister Packaging

Double blister packaging is a type of packaging where a product is sealed between two plastic blister shells. The shells are typically made of PVC or PET and are sealed together using heat or ultrasonic welding.

The Double Blister Packaging is popular for a wide range of products, including consumer electronics, toys, and small household items. It provides a clear view of the product and can be easily hung on display hooks. It is also relatively inexpensive to produce and provides a good level of tamper resistance.

What Are The Advantages Of Blister Packaging?

Blister packaging remains being one of the most popular packaging methods for many reasons. First, it is utilized for packing countless retail items, including tools, cosmetics, household products, and much more. This flexible option furnishes many advantages, so it is a go-to solution for various unique products. Other benefits include the following:

Good Protection

Because the blister pack has good sealing, it can be waterproof, moisture-proof, dust-proof, and rust-proof and extend the protection period.

Transparent and Intuitive

It is easy to see the shape and size of the goods through the transparent blister, and the substrate can print basic information such as commodity code, name, specification and barcode, which is convenient for the identification and quantity of the equipment in the package.

Easy to Use

The blister package is easy to open and convenient to use, and the sealing and protection of other products are not affected when using a single product.

Light Weight

The blister package is light in weight, and the blister has a certain elasticity, so it has a certain cushioning performance, and no additional cushioning material is required when packing, which saves storage space and reduces the cost of packaging.

Molds and Materials of Blister Packaging

What types of blister packaging are there?

The most common types of blister packaging are as follows:

Face seal blister

The plastic blister is moulded around the product and heat-sealed to a cardboard backing. This type of blister packaging is fairly inexpensive and so is generally used for products made in large volumes.

Full-face seal blister

The blister surrounds not only the entire product but the card backing too. The plastic is either heat-sealed to the card or slid through additional plastic pieces on each side. This type of blister packaging is used to make the packaging stronger (the corners are harder to bend, for instance) and better-looking.

Full card blister

Like the full-face seal blister, the blister covers the full size of the card. But rather than be heat-sealed to the card, it has flanges that wrap around it. The card is slid, and sometimes stapled, into place.

Trapped blister

A trapped blister is almost the same as a traditional blister pack but the plastic part that sticks to the cardboard has another piece of cardboard in front of it that fits around the shape of the blister. The plastic is then trapped between two pieces of cardboard. The top piece of card is die-cut to fit the blister where the product sits. As this type of blister packaging uses no heat-sealing methods, it’s cheaper to produce than those methods that do. This makes it more tamper-proof as it becomes obvious if the front cardboard has been ripped. It also looks better as it covers the plastic.

Clamshell Blister

A hinged blister where two sides fold together to create a closed container.

Clamshell packaging (also called clam packaging or clam packs) is a type of blister packaging. Unlike a normal blister pack, clamshell packaging doesn’t have a cardboard back. Instead, it has a plastic back which is hinged to the front of the packaging, either at the side or the base. Some versions are made so they can stand upright on shop shelves, while others are given a hole to be hung from racks. They might have a button to snap them closed, or be heat-sealed shut. The bubble can be evenly sized on the back and front or can be a different size and shape depending on the product inside it.

What products do blister packs suit?

Some products typically packaged with blister packs include:

- electronic goods and accessories (e.g. USB drives, cables, headphones)

- toys

- stationery (e.g. pens, drawing pins, paper clips, superglue)

- batteries

- toothbrushes and dental floss

- DIY goods (e.g. screws, nails, nuts and bolts)

- tablets and capsules

- products with delicate parts

- products that are vulnerable to breaking (e.g. printer ink cartridges)

Blister packaging is all about protecting the product. If the product’s shape makes certain parts of it vulnerable, blister packaging can protect it in a way that a bag or box can’t.

Blister packs also keep products clean and uncontaminated, which is why they are almost always used to package tablets.

They are also tamper-proof. In other words, if someone has tampered with a pack of tablets (e.g. removed some of the contents), you’d be able to see that clearly from a break in the packaging.

Blister Project Features And Design Parameters To Consider:

Blister card size: You always want your blister card to be as small as possible, as it will play a “cost” role in the sealing part of the process. Smaller is always better, but you need to balance that with the size of the product you are blistering, making sure you leave the proper amount of card space for effective graphics on the front and back of the card, which undoubtedly helps sell your product.

Hang Hole: Most every blister card has a die-cut hang hole. This is NOT an additional cost and is required by most retailers.

Foot: This is a protrusion of plastic specifically designed at the base of the PVC rigid blister, allowing your final blister package to stand vertically on a store shelf. Blisters designed with a foot would still have a hang hole in the blister card.

Artwork: All artwork is to be supplied by our customers. All art files should be in high-resolution Adobe Illustrator (.ai) file format. We recommend 4 colors plus any PMS colors for the front, but your least expensive printing option is to have only 1 color on the back of the card. This color should be black. Many customers prefer 4 colors on the back of the blister card, but this could double the price of the card.

Final Pack-Out options: Once your product is blister packaged, how do you want it packed into cartons that are shippable. Choices are master cartons (shippers), counter displays, POP displays, sidekick displays, PDQ displays, or club pack displays. We can help you determine the best option for your specific product.

Timelines and lead times: Once you have selected a card size and your artwork is completed, we will need a “production” sample of each of the products that will go into the blister package, and we can begin custom designing and prototyping the PVC blister for sign-off. Once we have artwork, we can have your complete project blister sealed and pack out in 3 weeks or less. This includes materials AND labor.